System examples

|

61

6 720 807 794 (2013/04)

UNIMAT

9.8

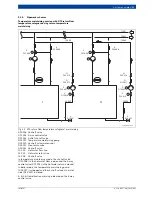

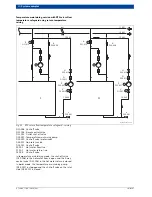

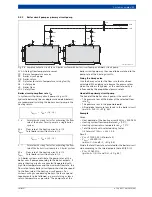

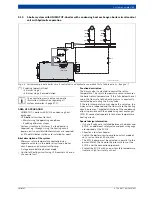

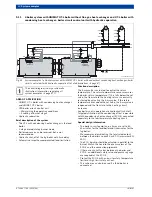

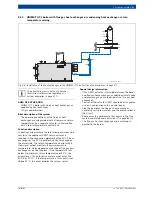

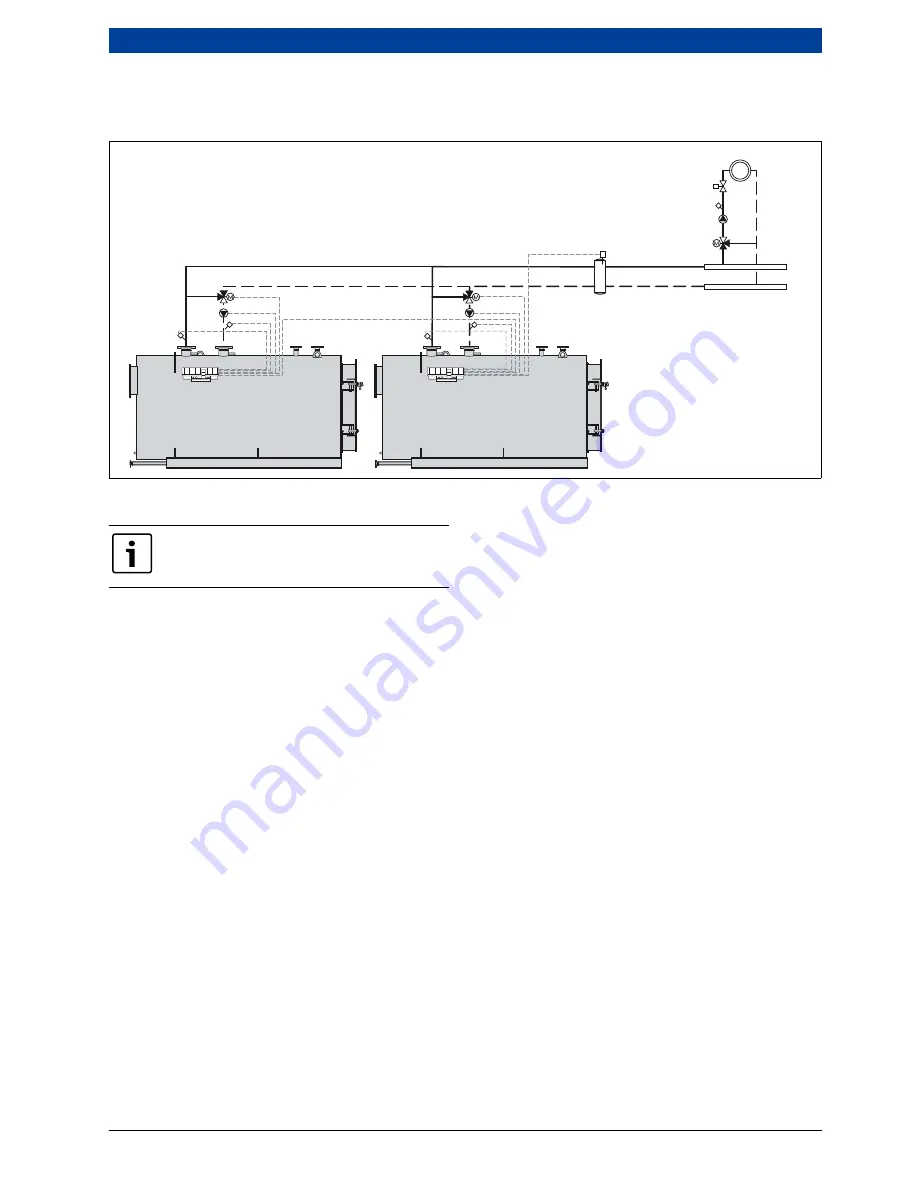

2-boiler system with two UNIMAT UT-L boilers: boiler circuit control unit with hydraulic

separation

Fig. 42 System example for a 2-boiler system with boiler circuit control unit and hydraulic separation (list of

abbreviations

page 47)

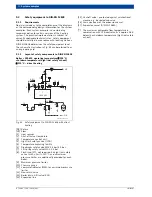

AREA OF APPLICATION

• UNIMAT UT-L boiler

• boiler circuit control unit

– Maintaining the operating conditions

– Enabling of burner stages

• Hydraulic separation

Brief description of the system

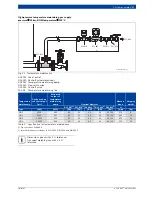

• Minimum return temperature controlled via a

separate actuator in the boiler circuit and a boiler

circuit pump

• Either serial or parallel operating mode

• 2-stage or modulating burner mode

• Boiler sequence can be reversed

• Hydraulic shut-off of the lag boiler with time delay

• Automatic or weather-compensated load limitation

• Control of heating circuit using CFB control unit or on-

site control unit

Function description

The 3-way valve is actuated to control the return

temperature. The return temperature sensor measures

the boiler return temperature. If this falls below the set

value, the flow rate to the return is constantly restricted

by actuating the 3-way valve. If the return temperature

rises above the set value, the 3-way valve is reopened

and the flow rate to the heating circuit increases. Any

boilers not in operation are hydraulically shut off.

Special design information

• Allow for a low loss header.

• The boiler circuit pump run-on time after burner

shutdown should be five minutes for the lag boiler,

and 30-60 minutes for the lead boiler.

• We recommend distributing the total rated output

between the boilers so each has 50 % (maximum 60/

40 %).

• This scheme can also be used if a third boiler is

connected.

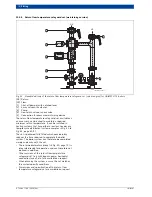

VK

RK

VK

RK

FZ

FK

FVS

FK

FZ

6 720 803 977-22.1itl

HK

PK

SH

PH

FV

THV

VV

VR

WH

PK

SR

SR

0

3

9

B

F

C

0

1

9

B

F

C

+ CMC 930

The circuit diagram is only a schematic

illustration! Information regarding all

system examples

page 47 ff.