Basic principles

|

7

6 720 807 794 (2013/04)

UNIMAT

2.2.2

High standard seasonal efficiency [to DIN]

The graphs in Fig. 4 and Fig. 5 show that the varying

proportion of condensation heat utilisation has a direct

influence on the energy utilisation of the condensing

boiler or boiler with condensing heat exchanger.

The high standard seasonal efficiency [to DIN] of gas

condensing boilers is based on the following influences:

• Achievement of high CO

2

levels. The higher the CO

2

content, the higher the dew point of the hot gases.

• Lower system and return temperatures can be

maintained. The lower the system and return

temperatures, the higher the condensation rate and

the lower the flue gas temperature.

The UNIMAT UT-L boilers can be matched individually

to the prevailing system characteristics and

requirements, subject to the individual project.

2.2.3

Design information

In new installations, every opportunity should be

exploited to achieve optimum operation of the

condensing boiler or boiler with condensing heat

exchanger.

A high standard seasonal efficiency [to DIN] is achieved

if the following criteria are satisfied:

• Limit the return temperature upstream of the

condensing heat exchanger to a maximum of 50 °C, at

least partially. In this connection, it is significant that

the separate connections for the boiler and

condensing heat exchanger mean a partial flow rate of

20 % with a low design temperature (e.g. 40/30 °C) is

sufficient to achieve excellent condensing efficiency.

• Aim for a temperature spread between the flow and

return of at least 20 K.

• Avoid installations for return temperature raising (e.g.

4-way mixers, bypass circuits, low loss headers,

depressurised distributors, etc.).

For more detailed information on the hydraulic

connection, see chapter 9 on page 47 ff.

2.3

Economic viability considerations

2.3.1

Simplified comparison of conventional boilers

and condensing boilers or boilers with

condensing heat exchangers

Fuel costs

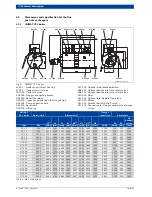

• Given

– Building heat demand

Q

N

= 2000 kW

– Annual heating energy demand

Q

A

=

3400000 kWh/a

– System design temperatures:

Ventilation

ϑ

V

/

ϑ

R

= 90/70 °C (proportion 20 %)

Radiators

ϑ

V

/

ϑ

R

= 75/60 °C (proportion 50 %)

Underfloor heating system

ϑ

V

/

ϑ

R

= 40/30 °C

(proportion 30 %)

– Fuel costs K

B

= 0.50 Euro/m

3

– Conventional UNIMAT UT-L boiler, rated output

2000 kW,

η

N

= 94,9 %

– UNIMAT UT-L boiler with condensing heat

exchanger, rated output 2000 kW,

η

N

= 102,3 %

The efficiency levels

η

N

specified for the UNIMAT UT-L

boiler with condensing heat exchanger apply if the

underfloor heating systems are connected separately to

the condensing heat exchanger.

• Sought

– Fuel consumption

– Fuel costs

• Calculation

F. 1

Calculation of annual fuel consumption

B

V

Annual fuel consumption in m

3

/a

η

N

Standard seasonal efficiency [to DIN] in %

H

i

Net calorific value; here natural gas simplified with

10 kWh/m

3

Q

A

Net heating energy demand in kWh/a

F. 2

Calculation of annual fuel costs

B

V

Annual fuel consumption in m

3

/a

K

B

Fuel costs

K

Ba

Annual fuel costs

• Result

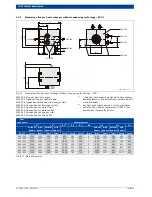

– UNIMAT UT-L boiler with rated output of 2000 kW:

Fuel consumption B

V

= 358272 m

3

/a,

Fuel costs K

Ba

= 179136 Euro/a

– UNIMAT UT-L boiler with condensing heat

exchanger, with rated output of 2000 kW:

Fuel consumption B

V

= 332356 m

3

/a,

Fuel costs K

Ba

= 166178 Euro/a

Central heating using the UNIMAT UT-L boiler with

condensing heat exchanger results in fuel cost savings of

approx. 11601 Euro per year.

B

V

Q

A

η

N

H

i

×

-----------------------

=

K

Ba

B

V

K

B

×

=