8

|

Technical description

UNIMAT

6 720 807 794 (2013/04)

Investment costs

The investment costs are based on the costs of a boiler

system. This includes the costs of the boiler, boiler

circuit control unit, pressure-jet burner and flue system,

as well as the costs of the safety equipment and return

flow temperature safeguard. The costs of the UNIMAT

UT-L boiler with condensing heat exchanger also include

the neutralisation of the condensate. Costs for

installation have not been taken into account.

Reflux of capital

In this example, the investment costs have been repaid

due to the lower fuel costs after about one year. It is

generally true that condensing technology pays for itself

faster the greater the output and the higher the fuel

costs. No subsidies have been taken into account in the

calculations. With the UNIMAT UT-L boilers, it is possible

to integrate further condensing heat exchangers. This

results in higher efficiency and therefore lower fuel

costs.

3

Technical description

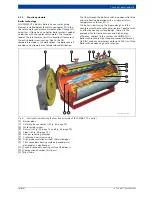

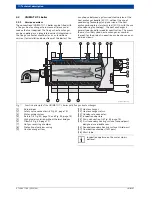

3.1

UNIMAT UT-L boiler

3.1.1

Equipment overview

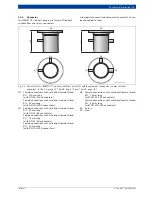

The UNIMAT UT-L boilers are oil/gas special boilers for

positive pressure combustion to EN 303. These boilers

are designed to produce low pressure hot water with no

more than 110 °C (shutdown temperature of the high

limit safety cut-out) for heating systems that correspond

to the demands of DIN-EN 12828. The permissible

overall pressure must not exceed the permissible

pressure stage of the boiler. The modular design of the

boiler and additional equipment enables universal

application.

• Round boiler casing made of textured aluminium

sheeting

• Visible parts of the boiler primed in anthracite grey

and red

• Thermal insulation (100 mm) and extremely well

insulated burner door

• Boiler pressure body with connections for flow,

return, safety valve and drain

• As an option with inspection port on the water side

• Bottom rear inspection aperture on flue gas collector

• Boiler base frame for even load distribution and easy

transportation

• Large burner door closing on the left hand side

(can be changed to the right hand side if required)

• Air-cooled combustion chamber sight glass

The following options are possible:

• Control unit holder

• Also available as a unit version (with boiler and

burner)

• Heat exchanger as integrated or stand-alone version

with and without the use of condensing technology

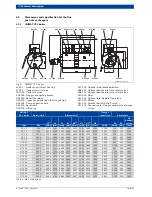

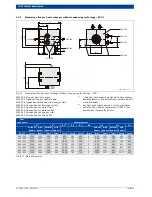

Scope of

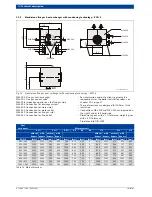

investment

1)

1) Incl. accessories

Unit

UNIMAT UT-L

boiler with a

rated output

of

2000 kW

UNIMAT UT-

L boiler with

condensing

heat

exchanger

with a rated

output of

2000 kW

Total

investment

costs

Euro

50000

63000

Table 2 Investment costs for conventional boilers and

boilers with condensing heat exchangers (values

rounded off)

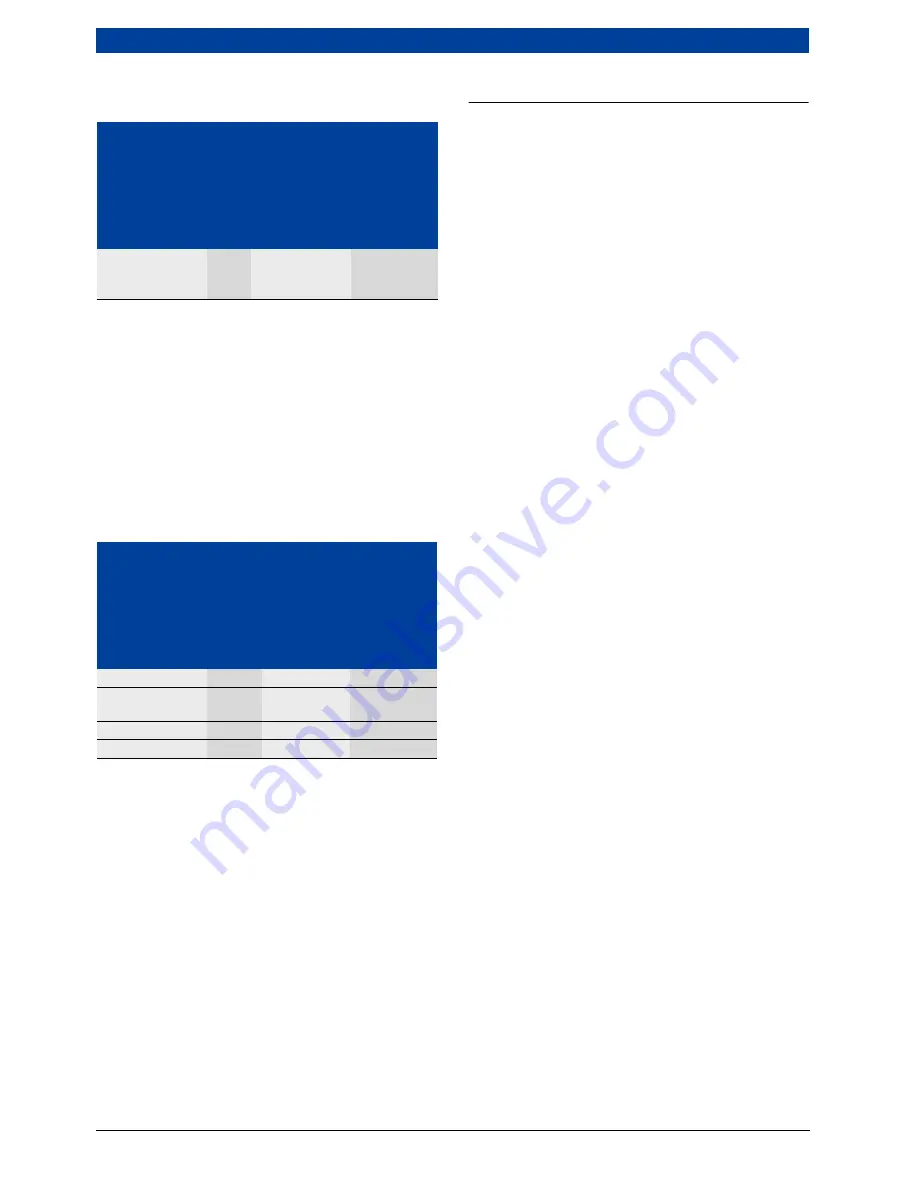

Type of cost

Unit

UNIMAT

UT-L boiler

with a rated

output of

2000 kW

UNIMAT UT-

L boiler with

condensing

heat

exchanger

with a rated

output of

2000 kW

Investment costs

Euro

50000

63000

Costs linked to

capital

1)

1) Annuity 9,44 %, interest 5 %, maintenance 1 %

Euro/a

5220

6577

Fuel costs

Euro/a

179136

166178

Total costs

Euro/a

184356

172755

Table 3 Total costs for conventional boilers and boilers

with condensing heat exchangers (values rounded

off)