Technical description

|

9

6 720 807 794 (2013/04)

UNIMAT

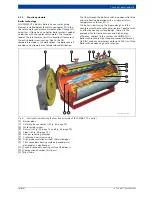

3.1.2

Function principle

Boiler technology

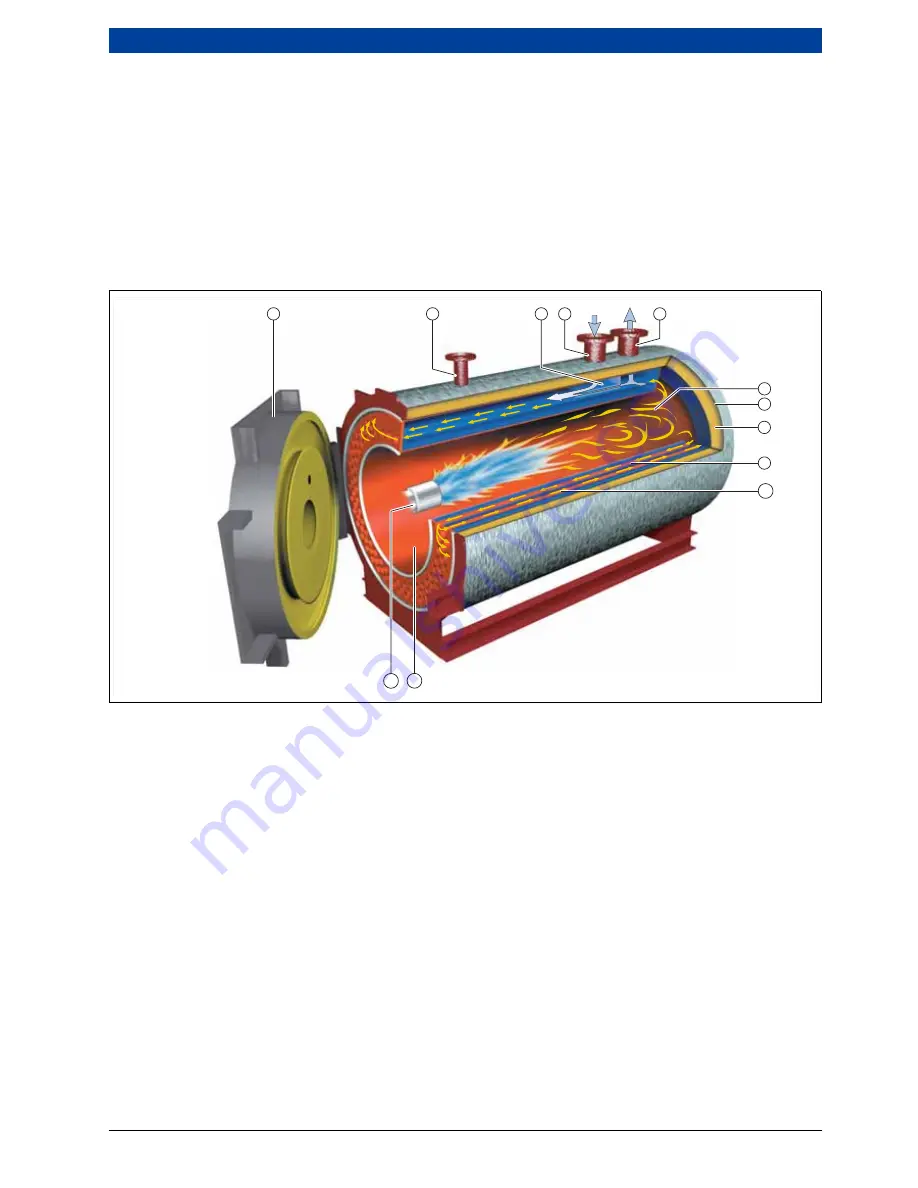

All UNIMAT UT-L boilers boilers have a water guide

element installed below the return connector. With this,

the return water generates an injector effect through its

velocity as it flows back, so hotter boiler water is added

and mixes with the cooler return water. The targeted

feed of the return water results in excellent flow across

the entire boiler cross-section. Due to the flat

temperature slope in the boiler block, the boiler overall

provides an extremely even temperature distribution.

The flow through the boiler results in condensation-free

and safe heating operation with a minimum return

temperature as low as 50 °C.

The boiler is built using the 3-pass design and the

countercurrent heat exchanger principle. Together with

an effective heating surface design, these are the

prerequisites for low emissions and high energy

efficiency. Subject to the system, the UNIMAT UT-L

boilers achieve very high standard seasonal efficiency

[to DIN], which can be increased to up to 106 % with the

boiler with condensing heat exchanger.

Fig. 6

Sectional view showing the function principle of the UNIMAT UT-L boiler

[1]

Burner door

[2]

Safety valve connector (

Fig. 51, page 73)

[3]

Water guide system

[4]

Return (

Fig. 50, page 72 and Fig. 53, page 76)

[5]

Flow (

Fig. 49, page 71)

[6]

Hot gas reversing chamber

[7]

Protective aluminium casing

[8]

High grade insulation without thermal bridges

[9]

First secondary heating surface (second pass)

designed as a double row

[10] Second secondary heating surface (third pass)

[11] Combustion chamber (first pass)

[12] Blast tube

1

2

12

11

4

5

3

10

9

8

7

6

6 720 803 977-01.1ITL