Maintenance / Care / Cleaning

Cleaning the drain pump

Cleaning is necessary:

If the pump is blocked by foreign

bodies (eg. Buttons, brackets) and the

water is not drained.

If lint is present after washing of

textiles.

When the pump is clogged, up to 20 liters of

water may leak. Provide a bucket.

Cleaning process:

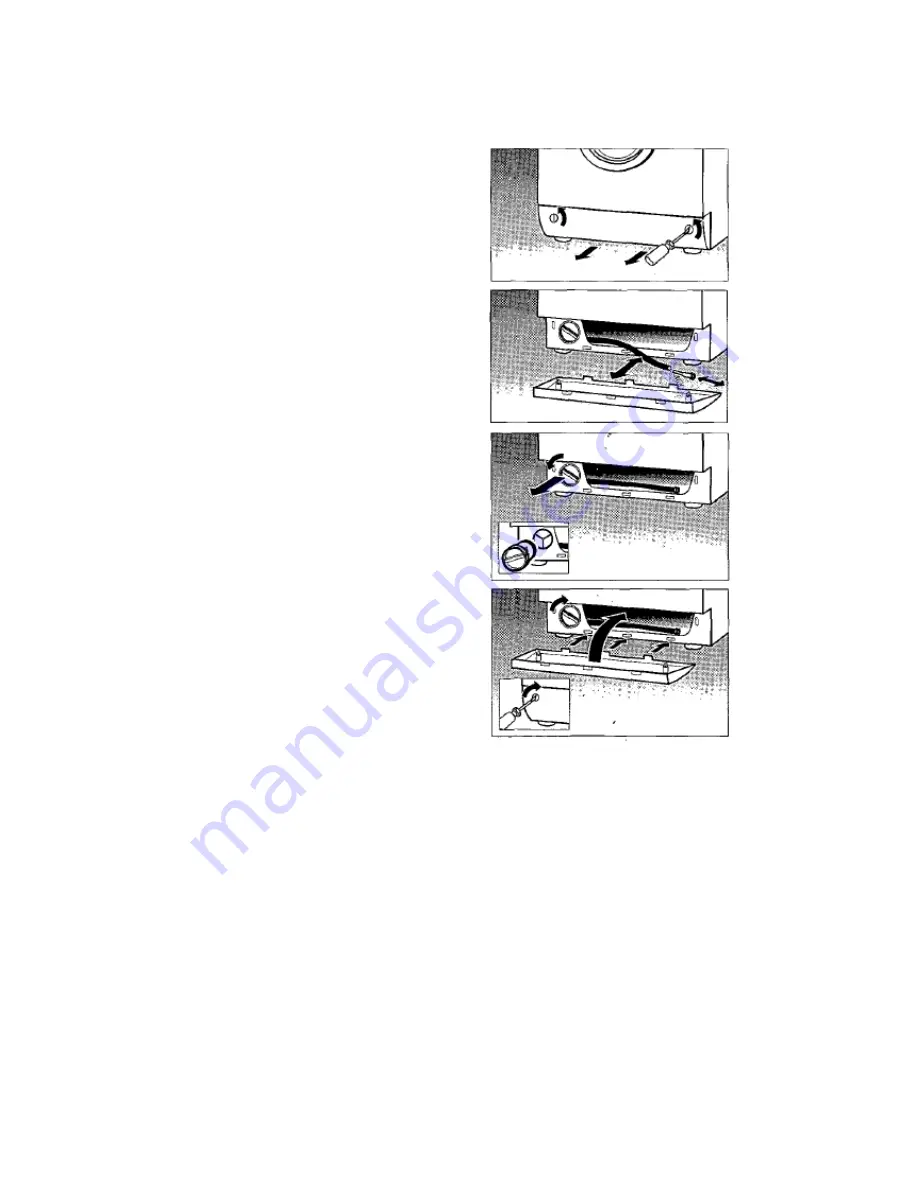

1. Remove the plinth at the front panel.

Danger of scalding! Allow hot detergent

solution to cool.

2. Pull breech plug from evacuation tube.

Allow water to leak into the plinth. If

necessary, repeat the process several times.

3 Replace plug seal and insert drainage hose.

4. Remove the pump cover.

5. Remove foreign bodies and deposits of

fluff. Clean the pump interior. Pump impeller

must be able to rotate.

6. Close pump tightly.

7. Re-attach and close plinth.

8. Pour about 2 liters of water into the

detergent chamber I and perform program

7

(pumping). This prevents unused detergent

from flowing in the next wash into the

drainage system.

Summary of Contents for WFF 16 series

Page 1: ......