Troubleshooting

en

51

Fault

Cause

troubleshooting

The programme duration

changes during the wash

cycle.

Note:

When loading, where possible,

place large and small items of laundry

together in the drum. Different sized

items of laundry distribute themselves

better during the spin cycle.

Foam detection system

switches on a rinse cycle if

foam build-up is too high.

▶

Not a fault – no action required.

No water is visible in the

drum.

Water is below the visible

area.

▶

Not a fault – no action required.

Drum jerks after the pro-

gramme starts.

This is caused by an internal

motor test.

▶

Not a fault – no action required.

Residual water is present in

the compartment .

Insert in compartment is

blocked.

▶

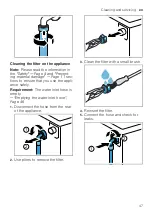

"Cleaning the detergent drawer",

Vibrations and movement of

the appliance whilst spin-

ning.

Appliance is not correctly

aligned.

▶

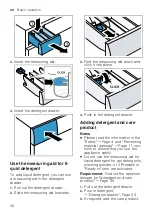

Aligning the appliance

The appliance feet are not

fixed.

▶

Secure the appliance feet. Aligning

the appliance

Transit bolts have not been

removed.

▶

Removing the transit bolts

Drum does not turn, water

does not flow in.

Load detection is active.

▶

Not a fault – no action required.

Note:

The load detection can take up

to two minutes.

Heavy foam build-up

Detergent dosage is too

high.

▶

Immediate measure: Mix one table-

spoon of fabric softener with 0.5

litres of water and pour the mixture

into the left-hand compartment (not

for outdoor clothing, sportswear or

items stuffed with down).

▶

Reduce the amount of detergent for

the next washing cycle with the

same load.

Noise

Fault

Cause

troubleshooting

Rushing, hissing noise.

Water is flushed under pres-

sure into the detergent

drawer.

▶

Not a fault – normal operating

noise.

Loud noises during the spin

cycle.

Appliance is not correctly

aligned.

▶

Aligning the appliance