Fault finding and diagrams

Greenstar Utility

ErP -

6 720 821 751 (2018/04)

41

8

Fault finding and diagrams

8.1

Fault finding

WARNING:

Under no circumstances must an appliance

be left to operate with any control linked out or

overridden.

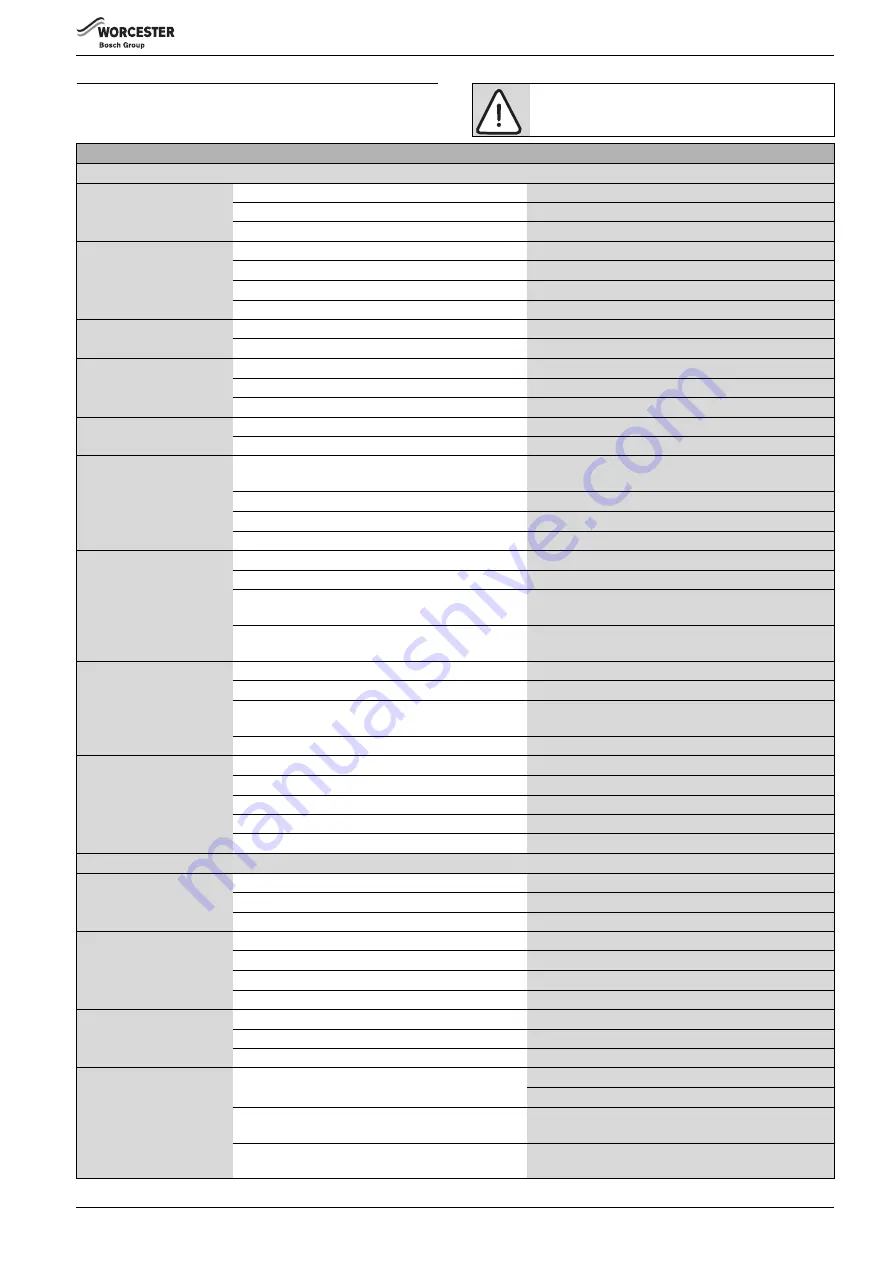

PROBLEM

CAUSE

REMEDY

LOCKOUT

Pulsation on start

CF - Flue draught incorrect

CF - Check flue draught

Combustion settings incorrect

Set up as in installation instructions

Faulty nozzle

Replace nozzle

Intermittent lockout

Bad electrical connection

Check control box/electrical connections

Combustion settings incorrect

Set up as in installation instructions

Intermittent flame detection fault

See flame detection fault

Down draught

Extend flue or fit an anti-down draught cowl (CF only)

Burner motor fails to operate Faulty motor or electrical supply to motor

Check for 230V to motor during startup period

Control box fault

Replace control box

Flame detection fault

Photocell filmed over (dirty)

Wipe clean

Photocell faulty

Replace

Control box faulty

Replace

Incorrect CO2

Air adjustment fault

Set up as in installation instructions

Oil pressure incorrect

Set up as in installation instructions

No oil from nozzle

No oil at pump

Check and refill oil tank/bleed oil line

Check and clean filters & valves from oil tank to appliance

Air in pump

Bleed pump

Nozzle blocked

Replace nozzle

Faulty pump or drive

Replace

Ignition failure

Electrode settings incorrect

Set up as in installation instructions

Faulty ignition transformer

Replace

Open circuit ignition

Check and replace electrodes or high tension leads if

necessary

Faulty control box or electrical connections not properly

made

Correct electrical control box connections or replace

control box

BURNER FAILS TO START

:

No power to appliance

Check electrical / control circuit

Programmer open circuit

Check programmer

Faulty appliance thermostat

Check by temporarily linking out high limit and control

thermostats

Faulty control box

Replace

HIGH SMOKE NUMBER

:

Air intake/flue blocked

Check & clear air intake/flue

Incorrect combustion settings

Set up as in installation instructions

Oil pressure incorrect

Adjust to correct pressure

Incorrect components used on combustion head

Check with installation instructions

Faulty nozzle

Replace nozzle

FAULTY APPLIANCE OPERATION

Noisy operation

Pump noise from air in pump or worn pump

Bleed air from pump or replace pump

Worn motor bearings

Replace motor

Fan out of balance

Replace fan

Boiling

No primary water circulation

Check system / circulating pump

Short circuit appliance thermostat

Temporarily take out of circuit to check

Thermostat bulb not fully home in pocket

Ensure bulb is pushed fully home

Faulty appliance thermostat

Replace if necessary

Short Cycling

External controls not operating correctly

Check and correct external controls

Appliance thermostat differential incorrect

Replace appliance thermostat

Burner rating incorrect

Correct burner rating

OIL SMELLS

:

Blocked flue, fumes on startup

CF - Check flue with gauge and check seals/gaskets

RS - Check seals/gaskets

Oil soaked appliance, faulty burner operation, numerous

lockouts

Rectify burner operation and lockouts

Odour in appliance room, oil leaks from pipework,

flexible hoses connections

Rectify oil leaks, replace components if necessary