13

Malfunction or failure

Greenstar Utility

ErP

– 6 720 821 750 (2018/04)

6.2

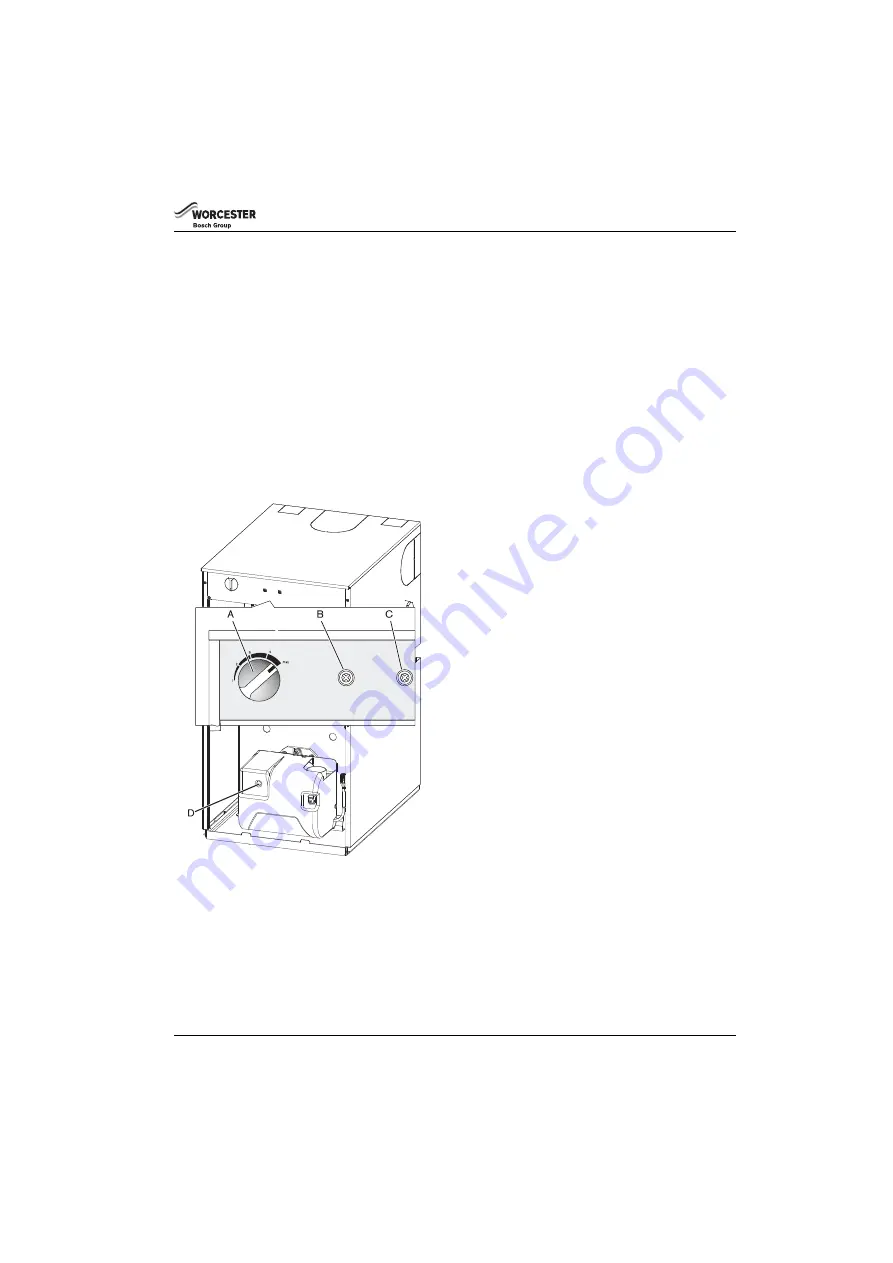

Controls behind the front panel

Temperature control [A]

▶ Remove the front panel and check the thermostat control

knob [A] is turned on.

– To remove the front panel pull the panel squarely away

from the front of the boiler.

– To replace, realign ball studs and push back into place.

Reset buttons [B, C & D]

▶ Remove the front panel and locate the reset button.

– To remove the front panel pull the panel squarely away

from the front of the boiler.

– To replace, realign ball studs and push back into place.

Always keep pressure to the edges of the panels to avoid

accidental damage.

Fig. 6

Controls behind the front panel

[A]

Temperature control

[B] Reset button - Flue overheat thermostat

[C] Reset button - Appliance overheat thermostat

[D] Reset button - Burner lockout

Appliance reset buttons

Automatic reset

▶ An excessive appliance operating temperature can activate

a thermostat to switch off the appliance. This thermostat

automatically resets when the appliance has cooled down

sufficiently.

Do not attempt to repeatedly start the appliance using the

manual reset buttons as persistent failure indicates a fault

requiring the attention of a service engineer.

Flue overheat [B] (manual reset)

▶ Excessive combustion gas temperatures can activate a

thermostat to switch off the appliance, indicated by button

standing proud. Press and release to reset thermostat.

Appliance overheat [C] (manual reset)

▶ Should the appliance temperature rise beyond the

automatic reset level, a high limit thermostat will switch the

appliance off, indicated by button standing proud. When

the appliance has cooled down, press and release to reset

the thermostat.

Burner lockout [D] (manual reset)

▶ Flame failure, for any reason, will cause the burner to go

safely to a lockout condition.

▶ Remove the appliance front panel and check the lockout

button. If this is illuminated it indicates a "lockout"

condition. To cancel lockout, wait 2 minutes, then press

and release the button.

6.3

Persistent failure

If the appliance fails to operate after following the previous

checks from the “Malfunction or failure” chapter 6, then a

safety device in the appliance control system may have been

activated to prevent the appliance from operating.

6720

821

750

-01

.1W

o