English

Installation and Safety Guidelines

Page 7

pro.Bose.com

Installation

5)

Choose fasteners to attach brackets to surface that are consistent with all local building codes and requirements to support the

loads depicted in Figure 3. As a general guideline, use 3/8

"

x 3" lag screws into wood and 3/8"-16 double expansion anchors into

concrete and masonry block.

6)

Drill holes into mounting surface using previously marked positions.

7)

Attach left and right brackets using required fasteners as outlined in Step 5.

8)

Install the supplied Channel Spacer part into the C-channel of both side-plates of the module. See Figure 4.

9)

Thread the supplied M10 bolt in the rear hole of the side-plate C-channel such that the bolt head extends out from the side plate.

See Figure 6.

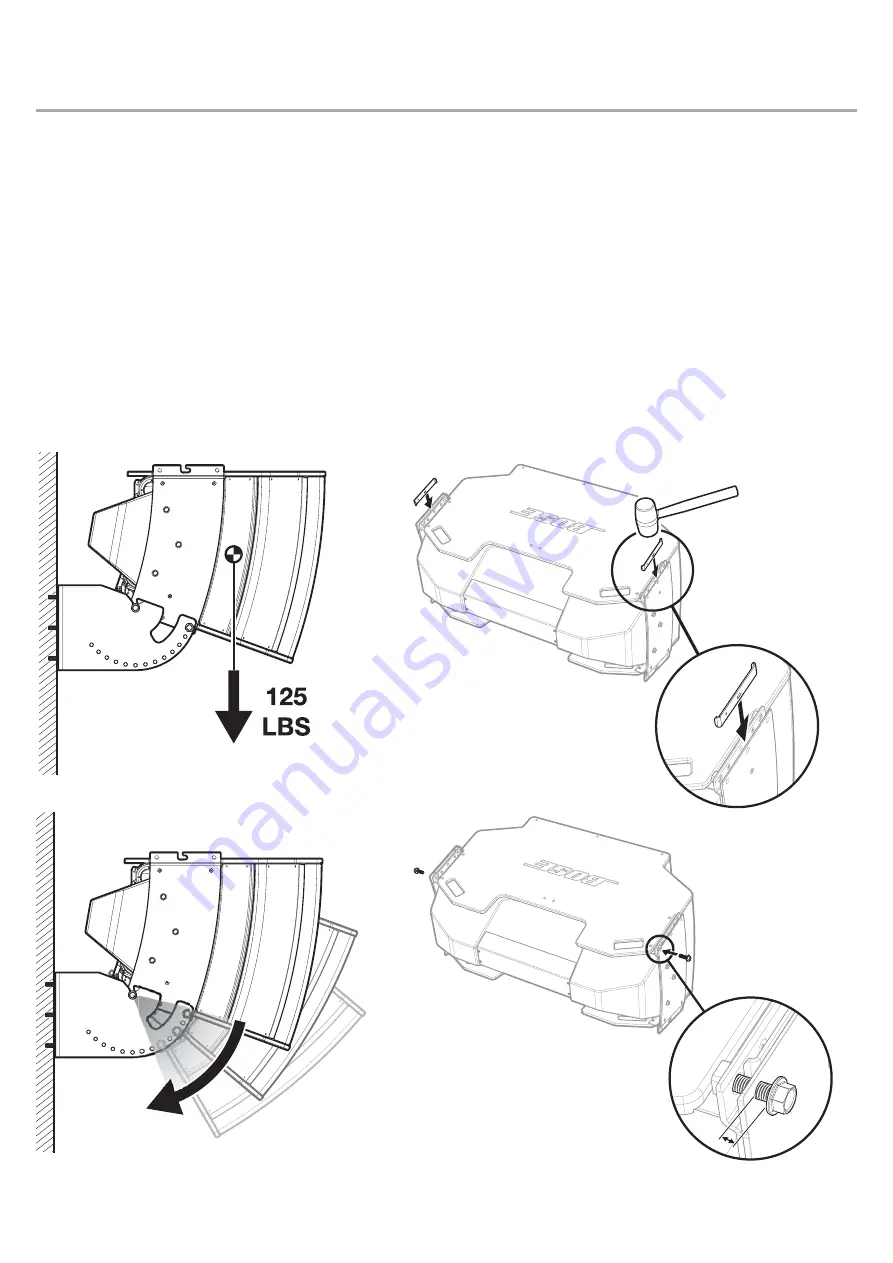

10) With 1 person per side, lift the loudspeaker module and position “upside down” such that the C-channel section of the side plates

is facing the ground.

11) Again using 1 person per side, lift the module to capture the rear fasteners that are protruding from the side plates and hook into

the rear bracket mounting slots. The rear fasteners can support the weight of the module, to allow alignment of the front mounting

holes for the required module pitch angle.

12) Align the front mounting hole with the proper pitch hole and insert two (2) M10 bolts, one per side. See Figure 5.

13) Tighten all 4 bolts with socket tool using torque not to exceed 35 to 40 foot-pounds (47 to 54 Newton-meters).

14) Connect field wiring, test loudspeaker operation.

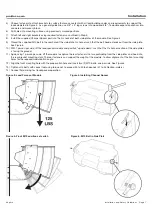

Figure 3. Load Forces of Module

Figure 5. Front M10 position sets pitch

Figure 4. Installing Channel Spacer

Figure 6. M10 Bolt in Side Plate