Page | 18

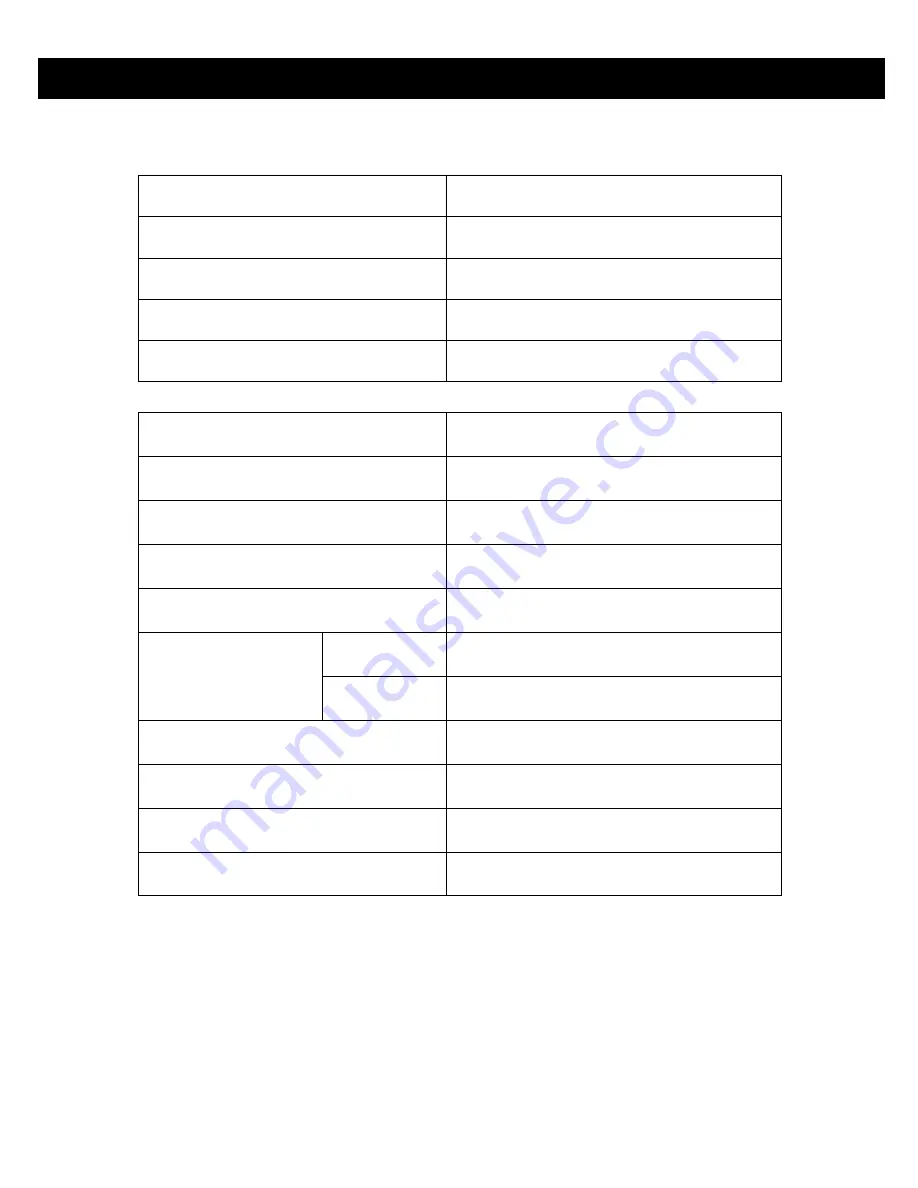

Electrical requirements

115V, 60Hz

Power output

1500W

Rated current

13.5A

Motor speed

3400 RPM

Power cable

SJTW 14 AWG (2.08mm²)

Max splitting force

7 ton

Max splitting length

20.5 in

Max splitting diameter

10 in

Hydraulic pressure

3500 PSI

Cylinder bore

2.2 in

Cycle time

Feed

9 sec

Retract

5 sec

Max cylinder stroke

17 in

Oil capacity

3.8 L

Machine dimensions (L×W×H) (in)

39.5x13.5x20

Machine net weight

106 lbs

TECHNICAL SPECIFICATIONS

Summary of Contents for ES7T20

Page 2: ......

Page 5: ...Page 2...

Page 22: ...Page 19 EXPLODED DIAGRAM PARTS LIST...

Page 26: ...Page 23 1 Log Splitter 1 Owner s Manual 1 Control handle 1 Hex Key PACKING LIST...

Page 27: ...Page 24...