Page | 20

REF #

PART #

PART NAME

SPECIFICATIONS

QTY PER SECTION

1

310-325

Machine Body w/ End Wedge

1

2

530-101

Ram Cap & Shaft

1

3

530-475

Upper Nylon Cushion

1

4

530-898

Lower Nylon Cushion

1

5

530-616

Base Plate of Ram

1

6

750-160

Flat Washer

M8*1

6

7

750-075

Spring Washer

M8*2.3

6

8

710-084

Inner Hex Bolt

M8*15

6

9

710-685

Double-Screw Bolt

M10*813

4

10

530-322

Cylinder Tube

Ø55*743

1

11

730-847

O Seal Ring

Ø55*3.1

1

12

730-446

Seal Cover

1

13

530-624

Piston Head

1

14

730-924

O Seal Ring

Ø50*3.5

1

15

530-434

Piston Shaft w/ Connecting Plate

1

16

530-580

Retracting Spring

1

17

720-156

Nut

M14

4

18

720-884

Lock Nut

M14

2

19

730-772

Paper Seal Ring

2

20

730-186

O Seal Ring

Ø30*2.65

1

21

730-139

Dirt Proof Ring

1

22

540-853

Front Reservoir Cover

1

23

730-094

O Seal Ring

Ø6*1

1

24

540-537

Vent Plug

M4*10

1

25

750-158

Copper Seal Washer

M14*1

1

26

540-333

Oil Dipstick w/ Oil Drain Bolt

1

27

520-974

Hydraulic Valve

1

28

730-198

O Seal Ring

Ø14*2.4

4

29

750-520

Flat Washer

M10*1

4

30

750-371

Spring Washer

M10*2

4

31

720-465

Nut

M10

4

32

350-233

Position Shield

1

33

750-525

Flat Washer

M10*2

4

34

720-678

Snap Head Nut

M10

4

35

520-596

Torsion Spring

1

36

520-293

Control Handle Bracket

1

37

520-401

Control Handle Lever w/ Grip

Ø12.5*134

1

38

560-587

Oil Tube

Ø14 - Ø10*100*1

1

39

730-624

O Seal Ring

Ø18*1.9

2

40

750-158

Copper Seal Washer

M14*1

2

41

710-896

Oil Tube Screw

M14*30

2

42

710-895

Inner Hex Head Bolt

M8*20

4

43

750-160

Flat Washer

M8*1

4

44

550-203

Hydraulic Pump

1

45

730-624

O Seal Ring

Ø18*1.9

1

46

560-587

Oil Tube

Ø14 - Ø10*100*1

1

47

750-158

Copper Seal Washer

M14*1

3

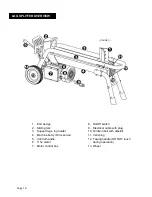

Summary of Contents for ES7T20

Page 2: ......

Page 5: ...Page 2...

Page 22: ...Page 19 EXPLODED DIAGRAM PARTS LIST...

Page 26: ...Page 23 1 Log Splitter 1 Owner s Manual 1 Control handle 1 Hex Key PACKING LIST...

Page 27: ...Page 24...