17.

Install the 5 carriage bolts (3/8 x 1 inch) and 5

nuts (3/8 inch) to the side bracket. Torque the 5

nuts from this step and 2 nuts from the previous

step to 41 N·m (30 ft-lbs).

g371992

Figure 38

18.

Install the lynch pin to the bristle carrier shaft.

g371999

Figure 39

Checking the Hydraulic

Fluid Level

Service Interval:

Before each use or daily

Refer to the

Operator’s Manual

.

Storage

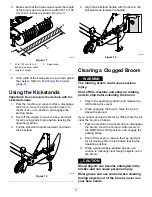

1.

Park the machine on a level surface, engage

the parking brake, and move the motion-control

levers outward to the N

EUTRAL

-L

OCK

position.

2.

Shut off the engine and remove the key.

3.

Lower the kickstands so that the bristles are

not touching the ground; refer to

Kickstands (page 9)

.

Note:

The bristles will become deformed and

the broom will be out of alignment if the bristles

are touching the ground for an extended period

of time.

4.

Disconnect the hoses from the low-flow

assembly and connect the hoses together.

5.

Disconnect the hoses from the high-flow

assembly and connect the hoses together.

6.

Cover the couplers of the high-flow and low-flow

assemblies using caps or a bag.

7.

Oil the chain; refer to

Oiling the Chain (page 11)

.

8.

Thoroughly clean the broom and ensure that it is

free of all caustic chemicals and/or residue.

9.

Check and tighten all bolts, nuts, and screws.

Repair or replace any part that is damaged or

defective.

10.

Paint all scratched or bare metal surfaces. Paint

is available from your Authorized Service Dealer.

11.

Store the broom in a clean, dry garage or

storage area. Cover it to protect it and keep it

clean.

15