19

309416

01/31/2012

6.3 Connecting the System Fuel Supply

Connect the fuel supply line to the 1/4” tube port on the starter side of the engine. Connect the fuel

return line to the 5/16” tube port, near the air inlet side of the turbo. Both tubes need to be SAE

30R7 rated fuel lines.

Installation

6.1 System Installation Overview

The 210 DUS Air Compressor should be installed only by those who have been delegated to do so,

trained, and who have read and understand this manual. Failure to follow the instructions, procedures,

and safety precautions in this manual may result in accidents and injuries.

Install, use, and operate this system only in full compliance with all pertinent O.S.H.A., Federal, State,

and Local codes or requirements, in addition to Boss Industries, Inc. and any company’s regulations.

Do not modify this system except with written factory approval.

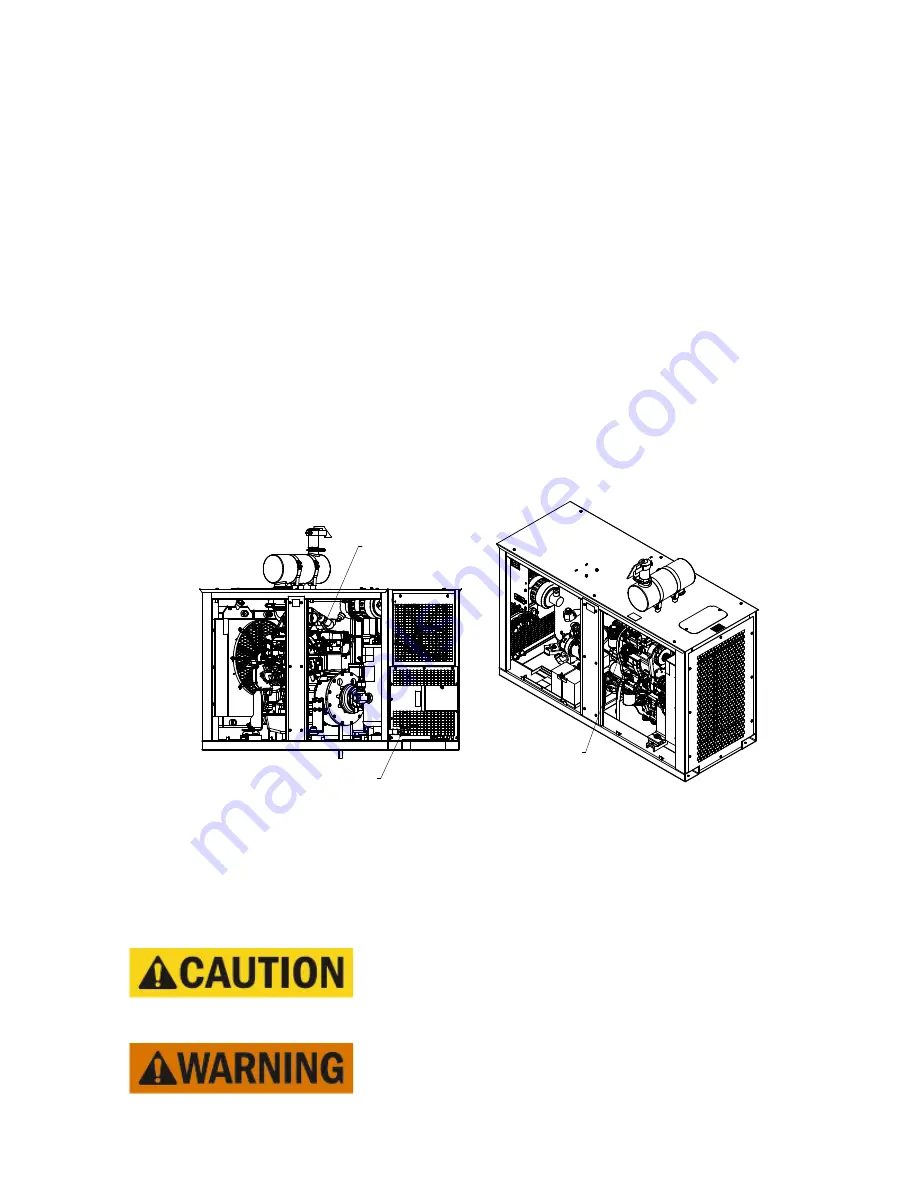

6.2 Placing The Machine

The first step in installing the 210 DUS Air Compressor is placing the system on a solid, level surface.

This machine is designed to run at up to a 15° grade maximum. The machine must be supplied ample

ambient air, as the system will overheat if the cooling air intake’s temperature exceeds ambient condi-

tions.

Do not mix gasoline or alcohol with diesel fuel. This mix-

ture can cause an explosion.

Due to the precise tolerances of diesel injection systems, it is

extremely important that the fuel be kept clean and free from

dirt or water. Dirt or water in the system can cause severe

damage to both the injection pump and the injection nozzle.

1/4" TUBE

FUEL SUPPLY

(2) 3/4" MNPT AIR

SERVICE VALVES

5/16" TUBE

FUEL RETURN