25

309416

01/31/2012

Maintenance

This section contains instructions for performing the inspection, lubrication, and maintenance procedures

required to ensure the system is in proper operating condition. The importance of performing the

maintenance described herein cannot be over emphasized. A planned program of periodic inspection

and maintenance will help avoid premature failure and costly repairs. Keep an accurate logbook for

maintenance, service, and operating hours. The maintenance schedule intervals on this system are

maximum intervals. The factory recommended maintenance schedule is based on favorable operating

conditions. For continuous duty, extreme temperature, etc., service more frequently. Neglecting routine

maintenance can result in machine failure or permanent damage.

This system should be maintained only by those who have been delegated to do so, trained, and who

have read and understand this manual. Failure to follow the instructions, procedures, and safety

precautions in this manual may result in accidents and injuries.

8.1 Maintenance Overview

8.2 Maintenance Schedule

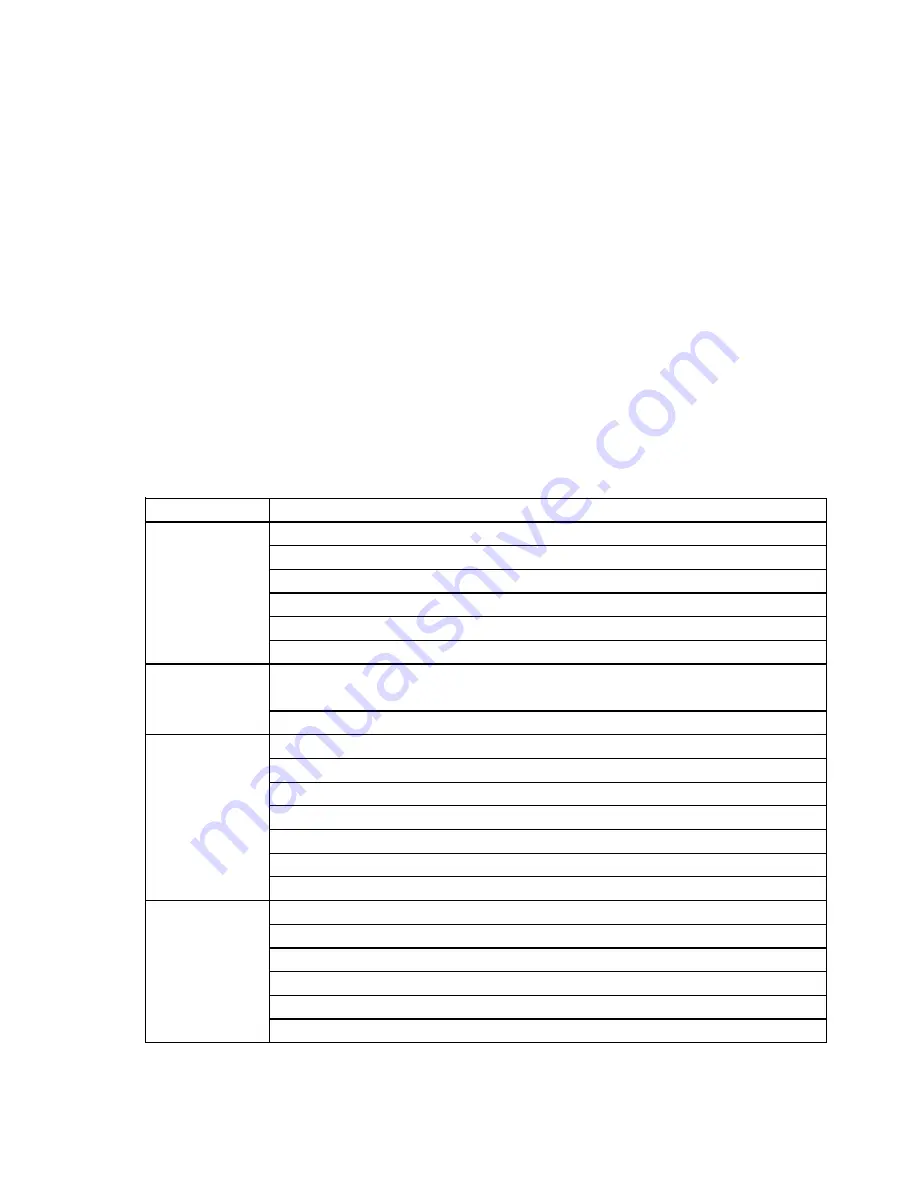

INTERVAL

REQUIRED MAINTENANCE

1. Check separator tank oil level.

2. Check engine coolant level in coolant recovery bottle.

3. Check engine air filter maintenance indicator.

4. Check for fuel, oil, air, and coolant leaks.

5. Check compressor air filter maintenance indicator.

6. Check battery hold down for security.

1. Drain water from separator tank. More frequent draining may be required

under high humidity conditions.

2. Inspect lifting frame.

1. Change compressor oil and oil filter element.

2. Clean battery terminals.

3. Check battery hold-down and cables for wear.

4. Check engine air filter connections, fittings, and clamps.

5. Check compressor air filter connections, fittings, and clamps.

6. Check radiator hoses and clamps.

7. Check integrity of engine mounts.

1. Install new air filter elements. (compressor and engine)

2. Check all door gaskets, hinges, and latches.

3. Clean and flush engine cooling system

4. Check separator tank pressure relief valve.

5. Clean cooler fins on all coolers.

6. Install new fuel filter and water separator elements.

EVERY 10

HOURS OR

DAILY

EVERY 50

HOURS OR

WEEKLY

EVERY 500

HOURS OR 6

MONTHS

EVERY 1000

HOURS OR 1

YEAR