Summary of Contents for 36 BHP PISTON

Page 2: ...2 309150 ...

Page 28: ...28 309150 ...

Page 29: ...29 309150 WARRANTY SECTION ...

Page 34: ...34 309150 ...

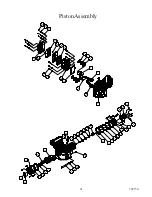

Page 35: ...35 309150 PARTS AND ILLUSTRATION SECTION ...

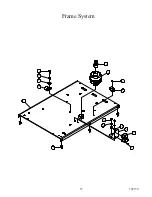

Page 37: ...37 309150 16 15 13 14 10 1 2 5 11 12 8 6 7 9 4 3 Frame System ...

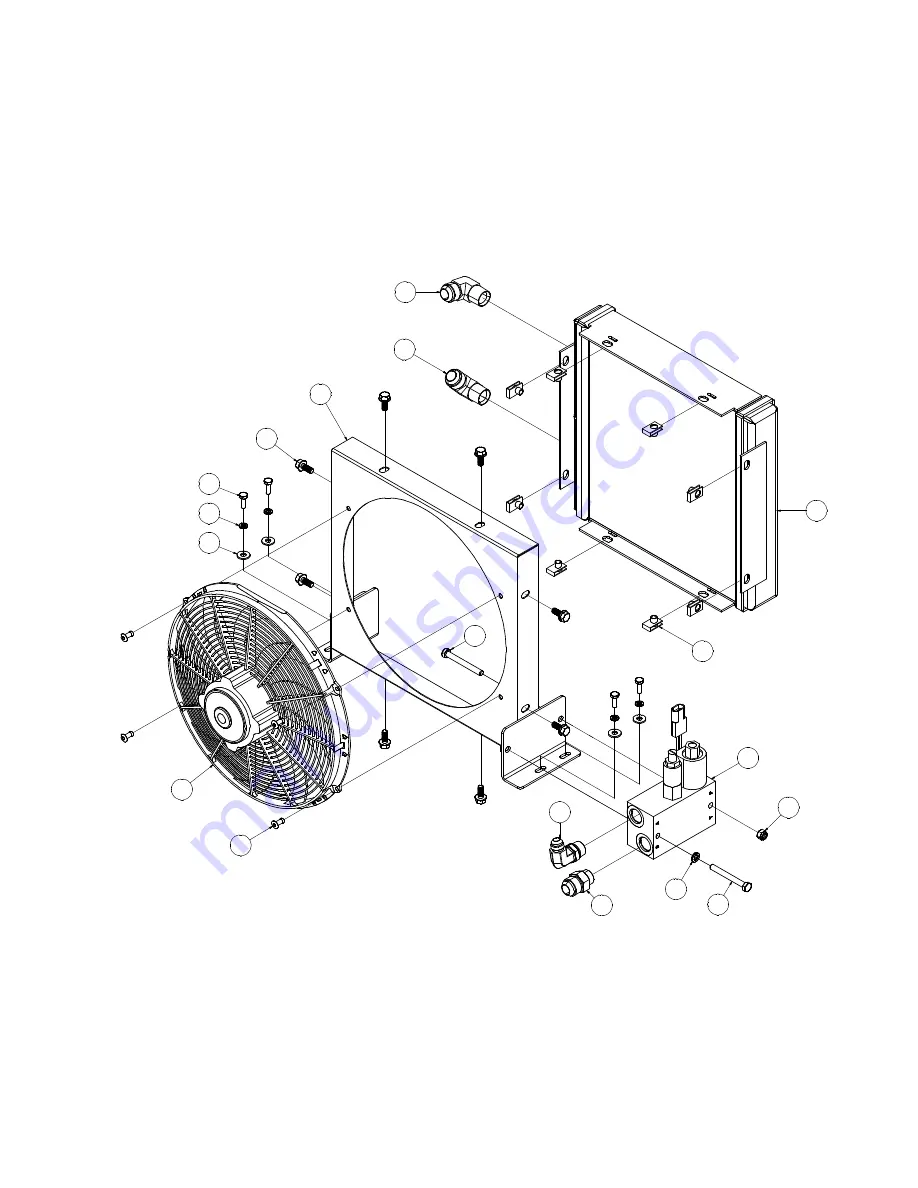

Page 43: ...43 309150 13 6 5 3 7 1 4 4 2 10 11 12 9 8 16 14 15 16 Cooler System ...

Page 45: ...45 309150 3 1 10 7 2 4 6 5 13 12 11 9 8 Hydraulic Drive System ...

Page 47: ...47 309150 2 3 4 6 5 1 7 Discharge System ...

Page 49: ...49 309150 Canopy System 11 13 4 6 7 1 12 2 2 8 3 4 10 9 5 ...

Page 51: ...51 309150 2J 2B 2C 2D 2J 2H 2E 1 2I 2G 2A 2F Decal System ...

Page 52: ...52 309150 System Schematic ...