21

MAINTENANCE

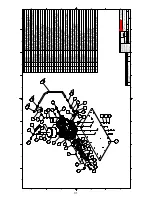

AIR/OIL COALESCER

The air/oil coalescer employs an element permanently housed within a spin-on canister. This is a

single piece unit that requires replacement when it fails to remove the oil from the discharge air, or

pressure drop across it exceeds 15 PSI. Dirty oil clogs the element and increases the pressure

drop across it.

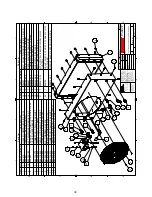

To replace element proceed as follows:

1. Shutdown compressor and wait for complete blow down (zero pressure).

2. Turn element counterclockwise for removal (viewing element from bottom).

3. Apply a film of fluid directly to seal on the new element.

4. Rotate element clockwise by hand until element contacts seal (viewing element from

bottom).

5. Rotate element approximately one more turn clockwise with band wrench near the top

of element.

6. Run system and check for leaks.

WARNING

COALESCER OIL RETURN

This originates at the bottom of the air/oil coalescer and flows through a special recovery pipe and

venturi nozzle. If the coalescer starts to fill with oil there is a good chance the venturi or pipe has

been plugged. Consult factory for cleaning instructions.

DO NOT SUBSTITUTE ELEMENT. USE ONLY A GENUINE BOSS INDUSTRIES

REPLACEMENT ELEMENT. THIS ELEMENT IS RATED AT 200 PSI WORKING

PRESSURE. USE OF ANY OTHER ELEMENT MAY BE HAZARDOUS AND COULD

IMPAIR THE PERFORMANCE AND RELIABILITY OF THE COMPRESSOR,

POSSIBLY VOIDING THE WARRANTY AND/OR RESULTING IN DAMAGE TO

PROPERTY AND SERIOUS BODILY HARM.

Summary of Contents for Infinity

Page 2: ......

Page 4: ......

Page 9: ...10 SAFETY ...

Page 28: ...29 PARTS AND ILLUSTRATION SECTION ...

Page 34: ...35 ...

Page 41: ...42 WARRANTY SECTION ...