24

TROUBLESHOOTING

This section contains instructions for troubleshooting the equipment following a malfunction.

The troubleshooting procedures to be performed on the equipment are listed below. Each

symptom of trouble for a component or system is followed by a list of probable causes of the

trouble and suggested procedures to be followed to identify the cause.

In general, the procedures listed should be performed in the order in which they are listed, although

the order may be varied if the need is indicated by conditions under which the trouble occurred. In

any event, the procedures which can be performed in the least amount of time and with the least

amount of removal or disassembly of parts, should be performed first.

UNPLANNED SHUTDOWN

When the operation of the machine has been interrupted by an unexplained shutdown, check the

following:

1. Check the fuel level and truck dash gauges and indications for possible engine

problems.

2. Check the compressor discharge temperature/switchgauge. If the latching relay circuit

is tripped the 12VDC solenoid will lose power and divert hydraulic oil back to the

reservoir. The compressor blowdown pressure switch and the temperature switchgauge

will not allow power to the hydraulic solenoid until the air has blown down and the

temperature has dropped into its normal operating range and the push button has been

reset. Take compressor in for service once a high temperature shutdown has occurred.

Failure to do so will void your warranty.

3. Check that the compressor oil is at proper level.

4. Check oil cooler for dirt, slush, ice on the fins, or any other obstructions to the cooling

air flow.

5. Make a thorough external check for any cause of shutdown such as broken hose,

broken oil lines, loose or broken wire, etc.

Summary of Contents for Infinity

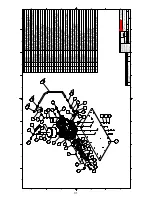

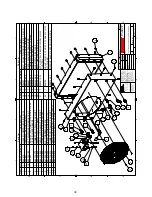

Page 2: ......

Page 4: ......

Page 9: ...10 SAFETY ...

Page 28: ...29 PARTS AND ILLUSTRATION SECTION ...

Page 34: ...35 ...

Page 41: ...42 WARRANTY SECTION ...