Electrical System Wiring Procedure

13

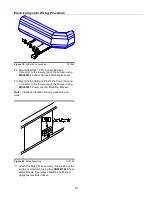

Figure 21.

Vehicle Option Connector

G10202

NOTICE

All plow wiring should be secured within the

engine compartment in a position that provides

sufficient room so that hot or moving parts will

not be contacted. Vehicle damage could occur if

wires are not properly secured.

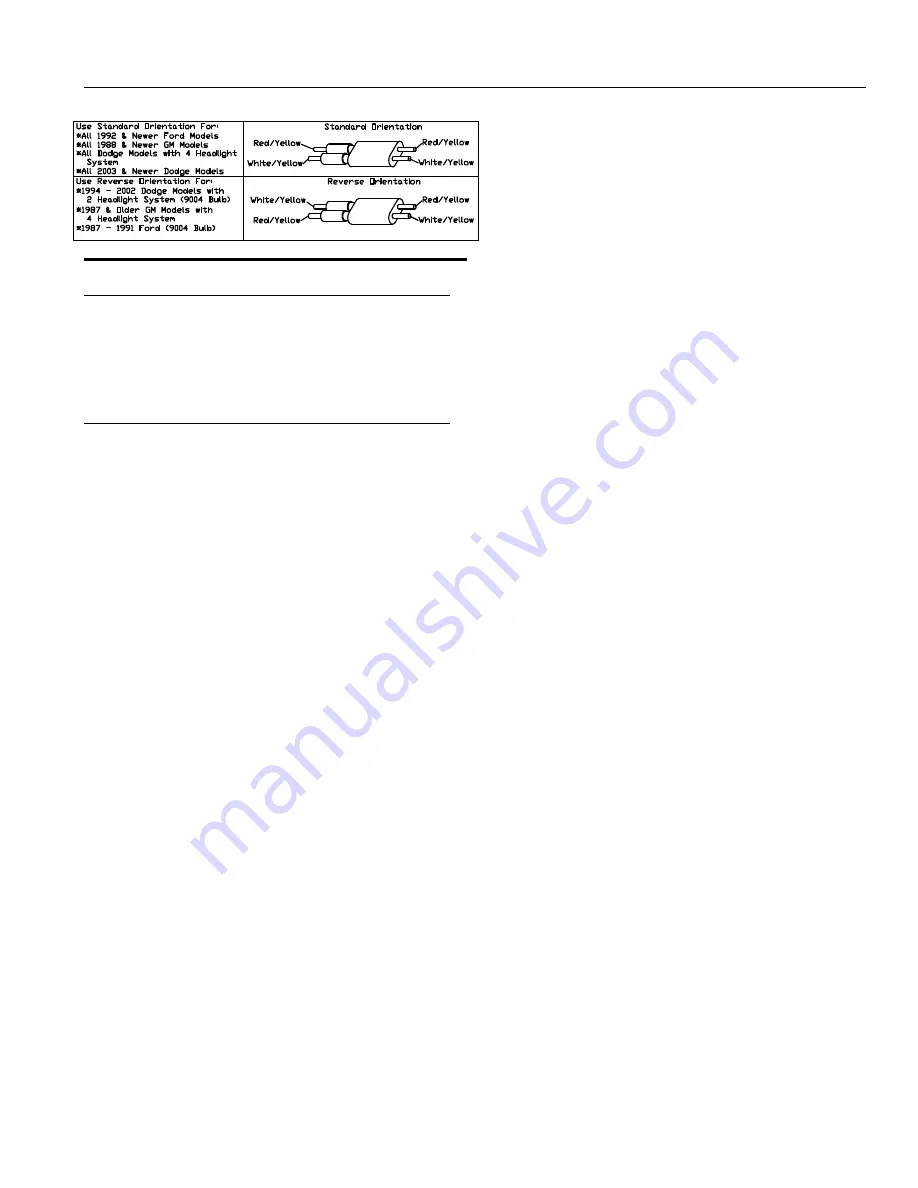

32. Locate vehicle option connector. Align the

connector so that the arrow on the Vehicle Option

Connector is positioned to match the vehicle it is

installed on. This is illustrated in Figure 21.

Note:

If your vehicle is not listed in the above figure

use the Standard Orientation. If the Vehicle Option

Connector is not properly connected the lights on the

plow will not function correctly.

33. Secure all plow harness wiring.

34. Attach the snowplow to the vehicle. Use the

“Snowplow Mounting Procedure” that is located in

this manual to properly attach the snowplow to the

vehicle.

35. Test for the proper operation of the Headlight

Wiring Harness. Follow the procedures below.

Note:

To test plow lights, the

IGNITION

must be in

the

ON

position.

•

LOW BEAM (Truck Lights)

♦

Vehicle Headlight Switch – ON

♦

Low Beam Lights on Truck Indicator

♦

Plow Headlight Toggle Switch –TRUCK

RESULTS

- ONLY vehicle low beam headlights should be illuminated.

•

HIGH BEAM (Truck Lights)

♦

Vehicle Headlight Switch – ON

♦

High Beam Indicator Light – ON

♦

Plow Headlight Toggle Switch –TRUCK

RESULTS

- Only vehicle high beam headlights should be illuminated.

•

LOW BEAM (Plow Lights)

♦

Ignition - ON

♦

Vehicle Headlight Switch – ON

♦

Low Beam Lights on Truck Indicator

♦

Plow Headlight Toggle Switch - PLOW

RESULTS

- ONLY plow low beam headlights should be illuminated.

•

HIGH BEAM (Plow Lights)

♦

Ignition - ON

♦

Vehicle Headlight Switch – ON

♦

High Beam Indicator Light – ON

♦

Plow Headlight Toggle Switch – PLOW

RESULTS

- Only plow high beam headlights should be illuminated.

•

TURN SIGNALS (Plow and Truck)

♦

Left Turn Signal Indicator – ON

RESULTS

- Both Left Plow and Left Truck turn signal bulbs should

be flashing.

♦

Right Turn Signal Indicator – ON

RESULTS

- Both Right Plow and Right Truck turn signal bulbs

should be flashing.

•

Park Lights (Plow and Truck)

♦

Park Lights on Vehicle – ON

RESULTS

- All four, Left Plow, Right Plow, Left Truck, and Right

Truck Park Lights should be on.

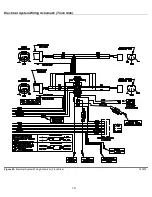

Note:

If any of the lights are not working properly, re-

check the wiring against the “Electrical Wiring

Diagram” located in this manual and make any

necessary corrections.