RT3 Headlight Aiming Procedure

20

Headlight Aiming

Procedure

NOTICE

The installer of these snowplow lights must

certify that installation conforms to applicable

Federal Motor Vehicle Safety Standards.

1)

Place the vehicle on a level surface 25 feet in

front of a matte-white screen, such as a garage

door. The screen should be perpendicular to both

the ground and the vehicle.

2)

The vehicle should be equipped for normal

operation. The snowplow blade should be in place

and in the raised position.

3)

Below are some points listed by the Society of

Automotive engineers (SAE) pertinent to headlight

aiming. These points can be found in publication

#SAEJ5991D.

Preparation for Headlight Aim or Inspection

Before checking beam aim, the inspector shall:

•

Remove ice or mud from under fenders.

•

See that no tire is noticeably deflated.

•

Check vehicle springs for sag or broken

leaves.

•

See that there is no load in the vehicle other

than the driver.

•

Check functioning of any “level-ride” controls.

•

Clean lenses and aiming pads.

•

Check for bulb burnout, broken mechanical

aiming pads, and proper beam switching.

•

Stabilize suspension by rocking vehicle

sideways.

4)

Mark (or tape) the vehicle centerline of the

headlights and the vehicle itself on the screen.

Mark the horizontal centerline of the headlights on

the screen (distance from ground to headlight

centers).

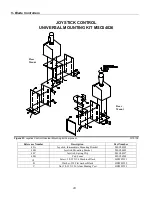

Figure 29.

Headlight Aiming Procedure

G10153

5)

The correct visual aim for Type 2 headlights is

with the top edge of the high intensity zone of the

lower beam below the horizontal centerline and

the left edge of the high intensity zone on the

vertical centerline. See diagram above.

25' From Headlights

Screen Located

Align With Vehicle

Centerline

of Right Headlight

Vertical Centerline Ahead

High Intensity Zones

For Type 2 (Sealed Beam)

Headlights on Low Beam

Headlight Centers

Distance Between