Troubleshooting Guide

27

PROBLEM

DIAGNOSTIC CHECK

RESULT

Check for voltage between

the other large terminal of

the solenoid and ground

while jumping power to the

small terminals with the

white wire.

If NO voltage is present,

solenoid has failed and

must be replaced. If voltage

is present, wire from small

terminal of solenoid to

ground may be

disconnected or broken.

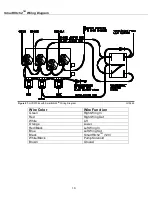

Test power to the control

box by checking voltage

between black wire and

ground at the white 9-pin

connector.

If NO voltage is present,

power from relay has

become disconnected. If

voltage is present check

wiring and controller

switches.

2. Pump continues to run

with switch in neutral.

Disconnect control box,

ignition ON.

If pump continues to run,

solenoid has failed in the

closed position. Quickly

remove power to the pump

by disconnecting the

power/ground cables to the

plow. Replace solenoid.

If pump stops running,

check wiring of controller

for short between black and

white/black wire in

controller, or failed switch.

3. Plow will not lower.

Check power/ground

cables and control cables

are connected properly.

Connect.

Check flow control valve.

If flow control valve is

completely closed, place

RAISE/LOWER switch in

NEUTRAL, then open the

flow control valve.

Check wiring on valve

block for proper

connections.

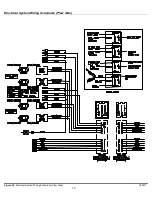

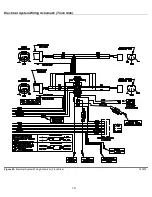

Refer to the wiring diagram

in this manual.

Check for voltage between

solenoid valve terminal

and ground with ignition

switch on and control

switch in FLOAT position.

If voltage is present

solenoid valve or valve coil

has failed. Replace valve.

Test power to the control

box by checking voltage

between black wire and

ground at the white 9-pin

connector.

If NO voltage is present,

power from relays has

become disconnected. If

voltage is present, check

wiring and switch of

controller.

4. Plow will not raise or

raises slowly (pump

motor runs).

Check hydraulic fluid level. Hydraulic fluid level should

be within ¾” from top of

reservoir when lowered and

in the V-position.