Troubleshooting Guide

29

PROBLEM

DIAGNOSTIC CHECK

RESULT

Check pressure at

pressure port of pump.

If pressure is less than

2500 psi (at end of lift).

Motor brushes may be

defective, pump pressure

relief valve may be

contaminated, damaged, or

set less than 2500 psi,

pump may be worn.

Check WING OUT

solenoid valve.

WING OUT solenoid valve

not opening completely.

Replace.

Check wiring and control

box.

9. Wing(s) extend, but will

not retract or retract

slowly.

Check power/ground

cables and control cables

are connected properly.

Connect.

Check wiring on valve

block for proper

connections.

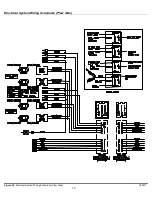

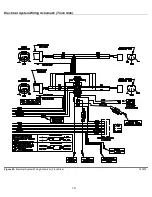

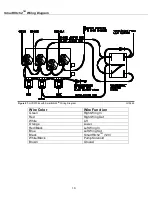

Refer to the wiring diagram

in this manual.

Check for voltage between

solenoid valve terminal

and ground with ignition

switch on and control

switch in WING IN

position.

If voltage is present,

solenoid valve or valve coil

has failed. Replace valve.

If NO voltage is present,

check wiring and switch box

control.

10. Wing(s) retract too

easily while plowing.

Pressure relief valve

pressure set too low.

See an Authorized BOSS

Dealer for pressure relief

valve adjustment.

11. Oil leaks from cylinders.

Loose packing.

Tighten packing 1/8-turn

increments until leak stops.

Check rod condition.

If rods are pitted or rough,

polish with copus cloth or

extra fine steel wool.

12. Battery goes dead with

all switches in neutral.

Possible short in switches. Inspect wiring of control box

switches, replace

switch(es).

Possible short in wiring

harness.

Repair damaged wire.

Possible short in valve

coils.

Replace coils.

13. Plow lights are dim, will

not come on or flicker.

Check electrical

connections.

Clean and repair any

corroded or damaged

terminals.

Check headlight adapter

wires.

Verify proper headlight

adapters are being used

and are correctly installed.

Check relays for corrosion

and function.

Relays should click when

energized.

14. Turn signals flash at a

rapid rate.

Check flasher.

Replace original vehicle

flasher with heavy-duty six-

lamp flasher provided.