B

D

E

A

C

1

2

PREPARATION

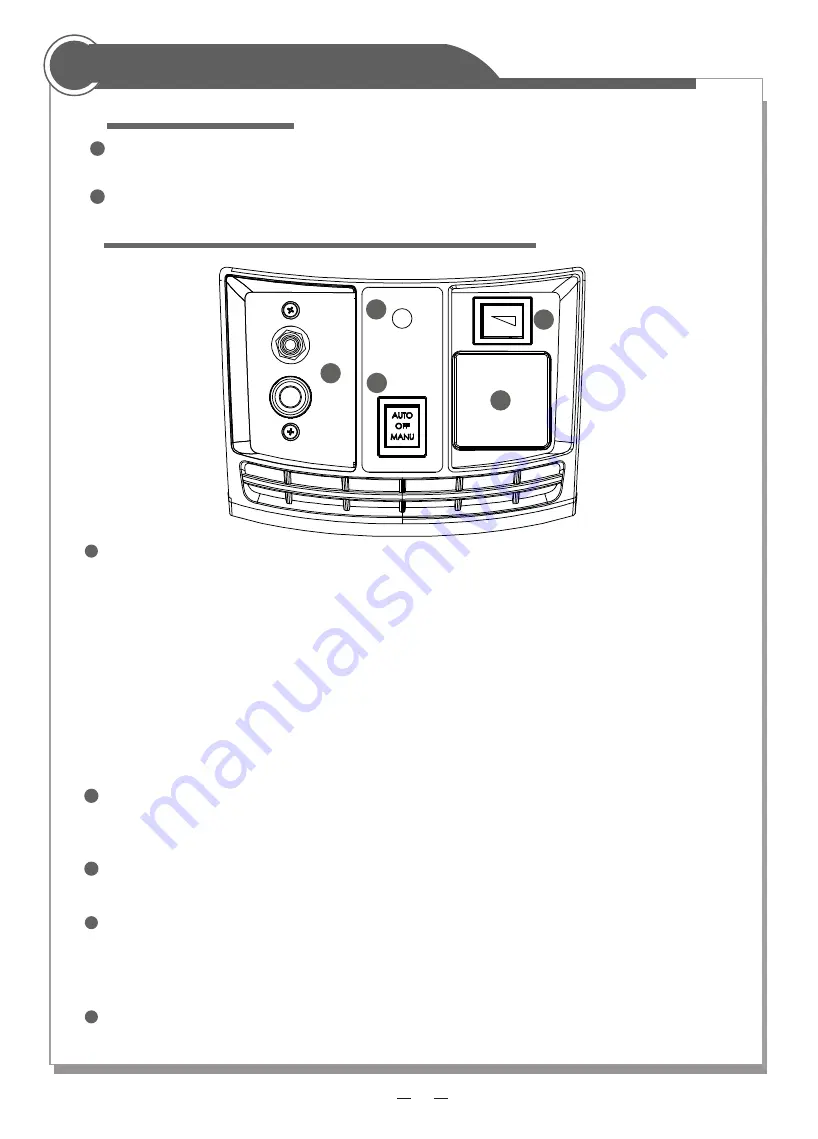

OPERATION INTERFACE INSTRUCTION

Operation Instruction

5

Open the host head before using. Install paper bag into the dust tank, then put back the host

head and clip side buckles tightly.

Insert 2 in 1 Suction hose into the pneumatic tool, ensure not coming off, and turn on the machine.

1

2

A

B

C

POWER SWITCH:

Switch at “

AUTO

” position, the vacuum to start control of the pneumatic tool or power tool.

When turn the switch to “

AUTO

” position, the vacuum cleaner will delay start about 3 seconds

, then will run for 1.5 seconds and then stop. It means the vacuum cleaner is on.

If the tool stops, the Vacuum cleaner will stop after running 5-10 sec.

●

●

●

Switch at “

MANU

” position can turn on the vacuum.

When turn the switch to “

MANU

” position, the Vacuum cleaner will delay start about 3 seconds

and then run continuously.

Turn the switch to “

OFF

” position,the vacuum cleaner will stop.

When finish working with vacuum cleaner, please turn the

AUTO- MANU

switch

at the

OFF

position.

Press the switch right will speed up, press it for 3 seconds to get the highest speed.

Press the switch left will slow down, press it for 3 seconds to get the lowest speed.

SUCTION POWER CONTROL:

OPERATION INDICATION LAMP:

It will be lit when the motor is on.

D

Note: the power of power tool can’t be over

1000W

, it will be overload and cause fire.

When turn the switch to “

AUTO

” position, the power tool using the plug can

control the

ON/OFF

of vacuum.

THE SOCKET OF POWER TOOL:

E

PNEUMATIC TOOL- TRIGGER MODULE CONNECTOR:

The quick coupling attached to the compressor and the other attached to the pneumatic hose.

05