INSTALLATION AND ADJUSTMENT

- 10 -

3 Installation and Adjustment

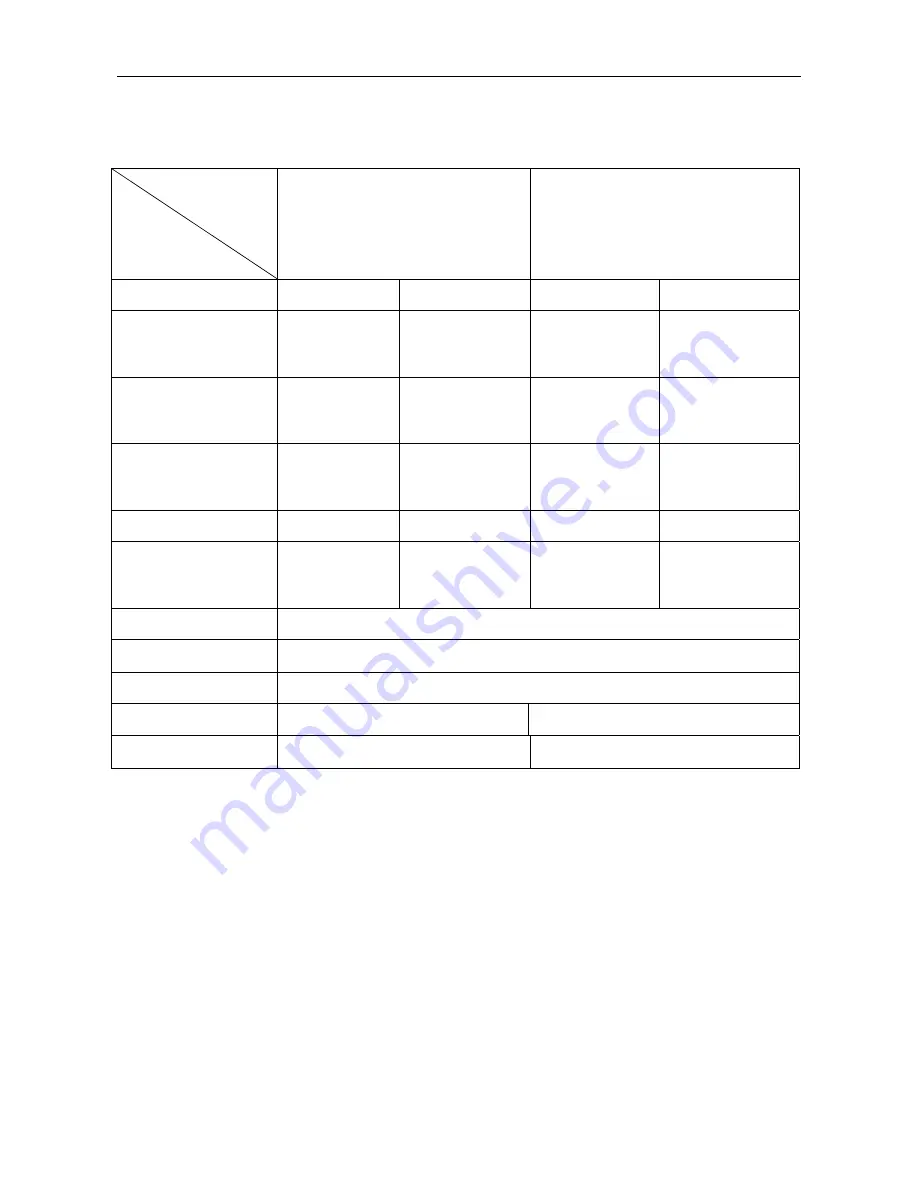

3.1 Parameters

Model

Parameters

MultiMIG200PFC

MST X250 PFC

Input Voltage

(

V

)

1-110

±10%

1-220

±10%

1-110

±10%

1-220

±10%

Input Current

(

A

)

MIG 31.7

MMA 32

TIG 19

MIG 26

MMA 30

TIG 19.5

MIG 43

MMA 37

TIG 32

MIG 43

MMA 44

TIG 36

Input Power

(

KW

)

MIG 3.4

MMA 3.5

TIG 2.1

MIG 5.7

MMA 6.6

TIG 4.2

MIG 4.7

MMA 4.0

TIG 3.5

MIG 9.4

MMA 9.6

TIG 7.9

Welding Current

(

A

)

MIG 40-140

MMA 10-110

TIG 10-150

MIG 40-200

MMA 10-200

TIG 10-200

MIG 40-160

MMA 10-130

TIG 10-130

MIG 40-250

MMA 10-250

TIG 10-250

No-load Voltage

(

V

)

66

66

66

66

Duty cycle

(

4

0℃)

MIG 140A30%

MMA 110A30%

TIG 150A40%

MIG 200A30%

MMA 200A25%

TIG 200A35%

MIG 160A35%

MMA 130A30%

TIG 140A35%

MIG 250A35%

MMA 250A30%

TIG 250A35%

Diameter(mm)

Fe

:

0.6

、

0.8

、

0.9

、

1.0

、

1.2 Ss 0.8

、

0.9

、

1.0

、

1.2

Protection class

IP23

Insulation class

H

Dimensions

(

mm

)

550*214*395

635*240*430

Weight

(

Kg

)

12.5

25

Note: The above parameters are subject to change with the improvement of machines.

3.2 Duty cycle and Over-heat

The letter “X” stands for the duty cycle, which is defined as the proportion of the time that a

machine can work continuously within a certain time (10 minutes). The rated duty cycle means

the proportion of the time that a machine can work continuously within 10 minutes when it

outputs the rated welding current.

The relation between the duty cycle “X” and the output welding current “I” is shown as the

right figure.