21

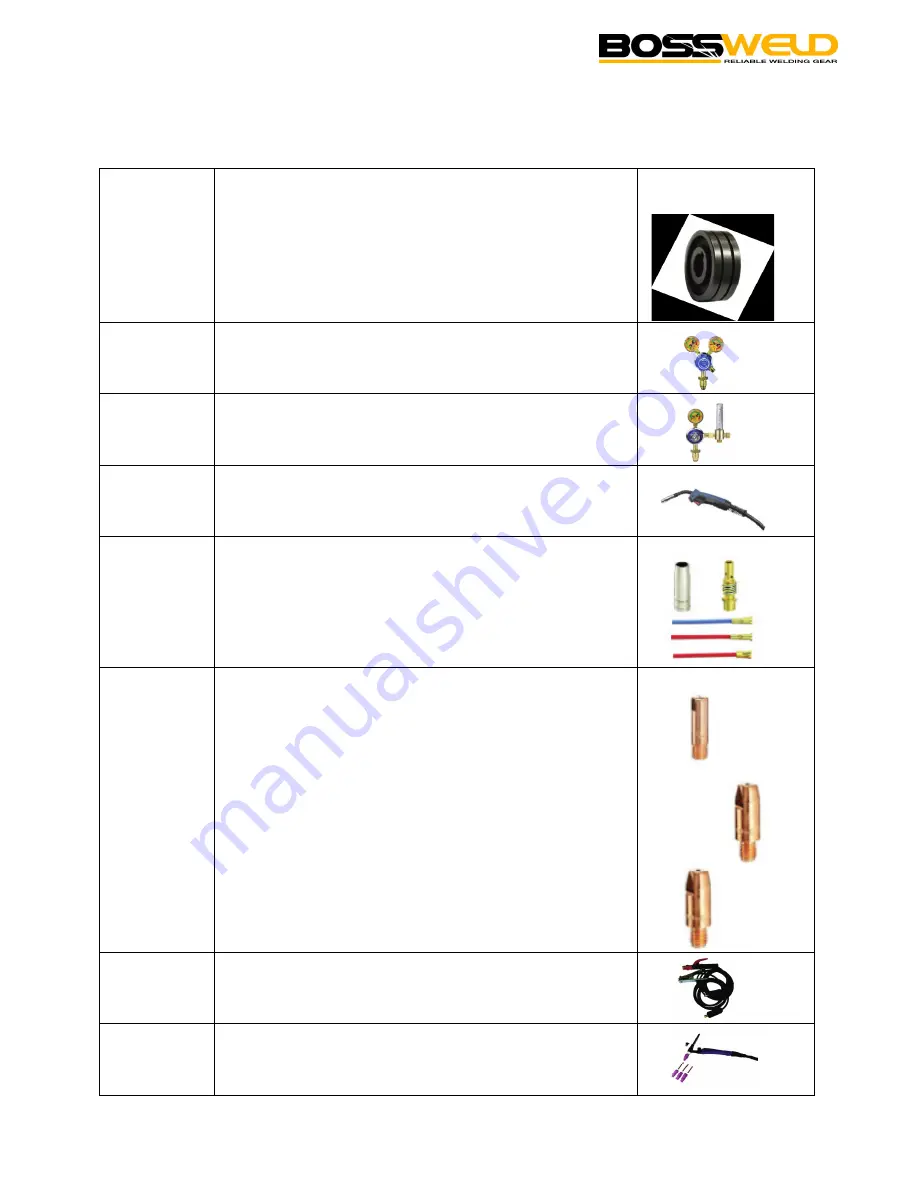

BOSSWELD TREO 175 COMMON PARTS LIST

600555

Drive Roller Treo 0.6/0.8mm V Groove (Solid wire)

600556

Drive Roller Treo 0.8/1.0mm V Groove (Solid wire)

600557

Drive Roller Treo 0.9/1.2mm V Groove (Solid wire)

600558

Drive Roller Treo 0.8/1.0mm U Groove (Aluminium)

600559

Drive Roller Treo 0.9/1.2mm U Groove (Aluminium)

600560

Drive Roller Treo 0.8/1.0mm Knurled (Flux cored)

600561

Drive Roller Treo 0.9/1.2mm Knurled (Flux cored)

400210

Bossweld Argon C02 Twin Gauge

400211

Bossweld Argon C02 Regulator - Bobbin type

92.ER.15.3

BZ15 Complete Mig Torch Ergon 3mt

92.02.15.CO

BZ15 Adjustable Conical Nozzle 12 Std

92.05.15

BZ15 Tip Holder with Spring Left Hand

92.03.15.01

BZ15 Spring for Tip Holder

92.04.B3

Blue Steel Liner 0.6 - 0.8mm wire -3 mt

92.04.R3

Red Steel Liner 0.9 - 1.2mm -3 mt

92.04.RT3

Red Teflon Liner 0.9 - 1.2mm -3mt

92.01.15.06

Contact Tip 0.6mm x 6mm dia x 25mm long

92.01.15.08

Contact Tip 0.8mm x 6mm dia x 25mm long

92.01.15.09

Contact Tip 0.9mm x 6mm dia x 25mm long

92.01.15.10

Contact Tip 1.0mm x 6mm dia x 25mm long

92.01.15.12

Contact Tip 1.2mm x 6mm dia x 25mm long

92.01.25.06

Contact Tip 0.6mm x M6 x 8mm dia x 28mm long

92.01.25.08

Contact Tip 0.8mm xM6 x 8mm dia x 28mm long

92.01.25.09

Contact Tip 0.9mm x M6 x 8mm dia x 28mm long

92.01.25.10

Contact Tip 1.0mm x M6 x 8mm dia x 28mm long

92.01.25.12

Contact Tip 1.2mm x M6 x 8mm dia x 28mm long

92.01.M6A09

Contact Tip 0.9mm x M6 Al x 8mm dia 28mm long

92.01.M6A10

Contact Tip 1.0mm x M6 Al x 8mm dia 28mm long

92.01.M6A12

Contact Tip 1.2mm x M6 Al x 8mm dia 28mm long

503316

Arclead Kit 175A 3m E.H./3m E.C. x 16mm

600550

TIG Torch Treo 17V, Dinse 50, QC Gas, 4mt

Summary of Contents for TREO 175

Page 1: ...User Manual TREO 175 ...

Page 11: ...11 Explanatory drawing for installation of TREO 175 STICK ...

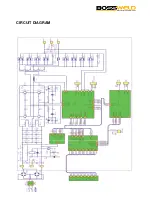

Page 22: ...22 CIRCUIT DIAGRAM ...

Page 30: ...30 Notes ...

Page 31: ...31 Notes ...