Trigger valve housing leaks air

O-ring cut or cracked . . . . . . . . . . . . . .Replace O-ring

Trigger valve stem leaks air

O-ring/seals cut or cracked . . . . . . . . . .Replace trigger valve assembly

Frame/nose leaks air

Loose nose screws . . . . . . . . . . . . . . . .Tighten and recheck

O-ring or Gasket is cut or cracked . . . . .Replace O-ring or gasket

Bumper cracked/worn . . . . . . . . . . . . . .Replace bumper

Frame/cap leaks air

Damaged gasket or seal . . . . . . . . . . . .Replace gasket or seal

Cracked/worn head valve bumper . . . . .Replace bumper

Loose cap screws . . . . . . . . . . . . . . . . .Tighten and recheck

Failure to cycle

Air supply restriction . . . . . . . . . . . . . . .Check air supply equipment

Tool dry, lack of lubrication . . . . . . . . . .Use BOSTITCH Air Tool Lubricant

Worn head valve O-rings . . . . . . . . . . .Replace O-rings

Broken cylinder cap spring . . . . . . . . . .Replace cylinder cap spring

Head valve stuck in cap . . . . . . . . . . . .Disassemble/Check/Lubricate

Lack of power; slow to cycle

Tool dry, lacks lubrication . . . . . . . . . . .Use BOSTITCH Air Tool Lubricant

Broken cylinder cap spring . . . . . . . . . .Replace cap spring

O-rings/seals cut or cracked . . . . . . . . .Replace O-rings/seals

Exhaust blocked . . . . . . . . . . . . . . . . .Check bumper, head valve spring, muffler

Trigger assembly worn/leaks . . . . . . . . .Replace trigger assembly

Dirt/tar build up on driver . . . . . . . . . . .Disassemble nose/driver to clean

Cylinder sleeve not seated correctly

on bottom bumper . . . . . . . . . . . . . . . .Disassemble to correct

Head valve dry . . . . . . . . . . . . . . . . . . .Disassemble/lubricate

Air pressure too low . . . . . . . . . . . . . . .Check air supply equipment

Skipping fasteners; intermittent feed

Worn bumper . . . . . . . . . . . . . . . . . . . .Replace bumper

Tar/dirt in driver channel . . . . . . . . . . . .Disassemble and clean nose and driver

Air restriction/inadequate air flow through

quick disconnect socket and plug . . . . .Replace quick disconnect fittings

Worn piston O-ring . . . . . . . . . . . . . . . .Replace O-ring, check driver

Tool dry, lacks lubrication . . . . . . . . . . .Use BOSTITCH Air Tool Lubricant

Damaged pusher spring . . . . . . . . . . . .Replace spring

Low air pressure . . . . . . . . . . . . . . . . . .Check air supply system to tool

Loose magazine nose screws . . . . . . . .Tighten all screws

Fasteners too short for tool . . . . . . . . . .Use only recommended fasteners

Bent fasteners . . . . . . . . . . . . . . . . . . .Discontinue using these fasteners

Wrong size fasteners . . . . . . . . . . . . . .Use only recommended fasteners

Leaking head cap gasket . . . . . . . . . . .Tighten screws/replace gasket

Trigger valve O-ring cut/worn . . . . . . . .Replace O-ring

Broken/chipped driver . . . . . . . . . . . . . .Replace driver (check piston O-ring)

Dry/dirty magazine . . . . . . . . . . . . . . . .Clean/lubricate use BOSTITCH

.Air Tool Lubricant

Worn magazine . . . . . . . . . . . . . . . . . .Replace magazine

Fasteners jam in tool

Driver channel worn . . . . . . . . . . . . . . .Replace nose/check door

Wrong size fasteners . . . . . . . . . . . . . .Use only recommended fasteners

Bent fasteners . . . . . . . . . . . . . . . . . . .Discontinue using these fasteners

Loose magazine/nose screws . . . . . . . .Tighten all screws

Broken/chipped driver . . . . . . . . . . . . . .Replace driver

-10-

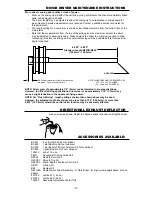

TROUBLE SHOOTING

COIL NAILERS

Skipping fasteners; intermittent feed

Feed piston dry . . . . . . . . . . . . . . . . . .Add BOSTITCH Air Tool Lubricant

in hole in feed piston cover

Feed piston O-rings cracked/worn . . . .Replace O-rings/check bumper and spring.

Lubricate assembly.

Check Pawl binding . . . . . . . . . . . . . . .Inspect Pawl and spring on door.

Must work freely.

Canister bottom not set correctly . . . . .Set canister bottom for length of nails

being used

Broken weld wires in nail coil . . . . . . . .Remove coil of nails and use another coil

Fasteners jam in tool/canister

Wrong size fasteners for tool . . . . . . . .Use only recommended fasteners/check

canisterbottom adjustment

Broken welded wires in nail coil . . . . . .Remove coil of nails and use another coil

Wrong slide plate adjustment for

wire/plastic collated nail coil . . . . . . . . .Adjust switch pins for wire/plastic collated

nail coil

PROBLEM

CAUSE

CORRECTION