Boston Gear • 800-825-6544

P-3003-BG

13

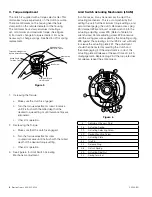

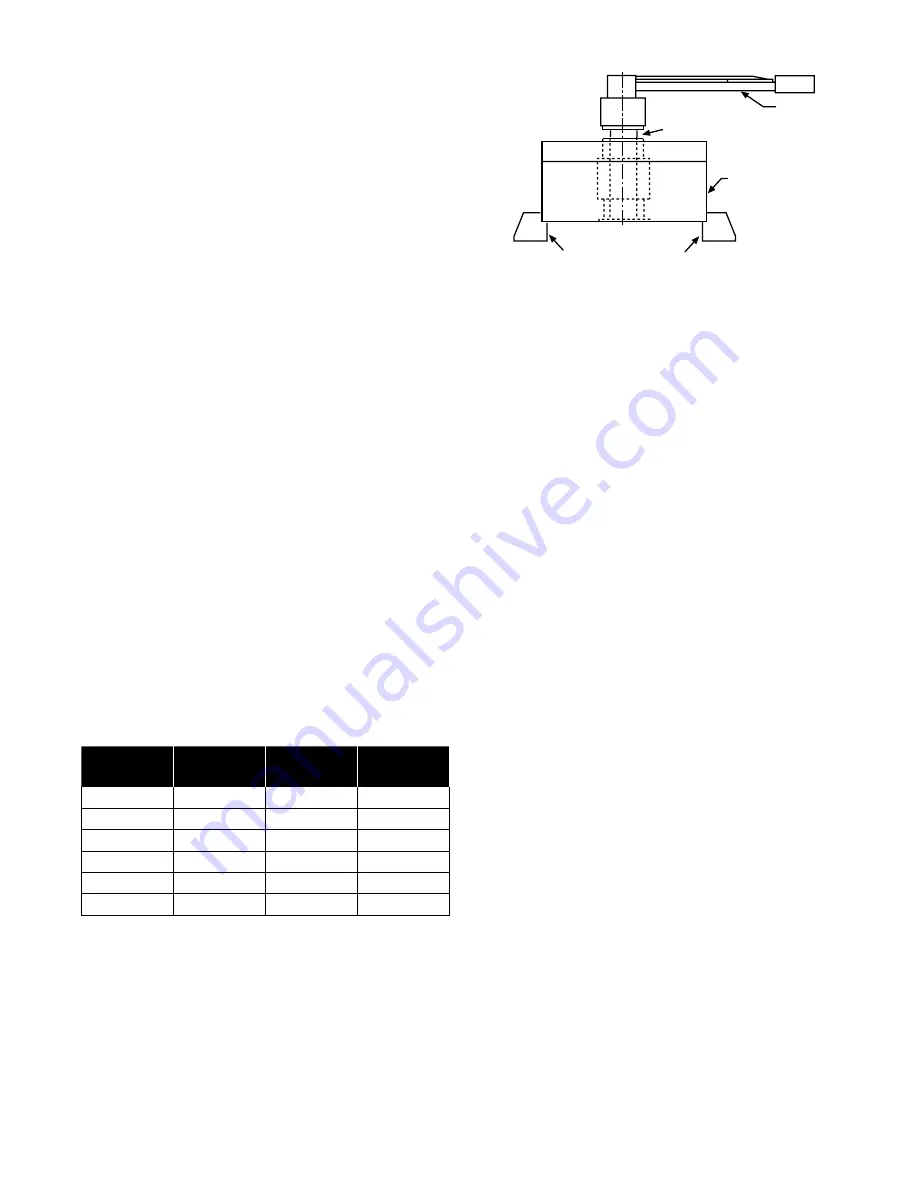

C. Torque Verification

1. Place the clutch in a chuck or vise with the cover

facing upward.

2. Insert the appropriate size arbor and key into rotor.

(See Figure 18)

3. Turn the drive spring screw (21) clockwise until it is

flush with the surface of the housing.

4. The clutch is supplied with a torque selector dial.

The torque selector dial is the mill marks located at

the hole stamped 9 on the housing. If a drive spring

(18), reset spring (19), and/or a reset spring screw

(14) were replaced, chances are that the stamped

torque values on the dial are no longer valid. It may

be necessary to grind the old numbers off and to

stamp new ones.

5. Tighten the reset spring screw (14) until it reaches

the limit stop pin (4). This will be the maximum

torque position. If the maximum torque is not

desired, tighten the reset spring screw to one of the

locations on the torque selector dial.

6. Disengage the clutch with a torque wrench. Fine

tune the torque by turning the drive spring screw

(21) until the desired release torque is obtained.

7. Refer to Section I, C for further details on torque

adjustment.

8. Once the desired release torque is obtained, tighten

the locking screws (25) located over the drive spring

and reset spring screws to ensure that they will not

move. The unit is now ready for installation. Refer to

Section lll for installation of basic clutch.

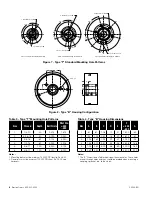

Table 10 - Cover Screw Seating Torques

Clutch

Size

Screw Size

Quantity

Seating

Torque

1

1/4-20

3

100 in.lb.

2

5/16-18

3

200 in.lb.

3

3/8-16

3

350 in.lb.

4

1/2-13

4

850 in.lb.

5

5/8-11

4

1,700 in.lb.

6

5/8-11

4

1,700 in.lb.

Figure 18

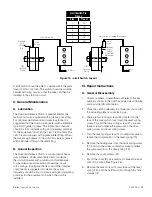

D. Limit Switch Actuating Mechanism (LSAM)

Assembly

1. Apply a graphite lubricant to the release ring groove

of the cover (8).

2. Insert the actuating stud (40) through the appropriate

hole in the release ring (35). To identify this hole

place the release ring in the groove of the cover.

When the trip pin holes line up with the through

holes of the cover, the actuating stud hole will line

up with the counterbored hole in the groove of the

cover.

3. Install the actuating stud nut (39) onto the actuating

stud (40) and tighten.

4. Install a spring terminal (43) on each end of the

return spring (38). Clutch sizes 5 & 6 require two

return springs.

5. Insert a spring terminal screw (41) through the hole

of the spring terminal (43), and place a spacer collar

(36) on the end of the screw. Insert the end of the

screw into the threaded hole of the release ring (35)

and tighten. The end of the screw may protrude past

the release ring. Grind the end of the screw flush

with the surface of the release ring. Install second

spring terminal screw on clutch sizes 5 & 6 as just

described. Move to Step 13 for clutch sizes 5 & 6.

6. Press the trip pins (32) into the trip plate (31).

7. Install a bowed snap ring (34) into the groove of

each trip pin located next to the trip plate.

8. Place the trip plate flat on a table with counterbored

holes facing up. Insert the thrust springs (37) into the

counterbores.

Torque Wrench

Arbor

Trig-O-Matic Clutch

Vice or Chuck Jaws