14

Boston Gear • 800-825-6544

P-3003-BG

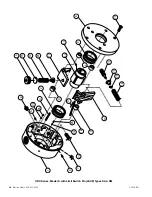

9. Place the cover (8) over the trip plate, lining up the

counterbores in the cover with the springs.

10. Place the release ring (35) into the groove of the

cover. Make sure that all of the holes line up properly.

11. Insert a spring terminal screw (41) through the hole

of the other spring terminal (43) and place a spacer

collar (36) on the end of the screw. Insert the end

of the screw into the tapped hole of the cover and

tighten.

12. Push down on the cover and release ring until the

release ring engages into the grooves of the trip

pins. Install two snap rings (33) into the grooves of

each trip pin. Move to Step 22.

13. Place the release ring (35) into the groove of the

cover. Make sure that all of the holes are properly

aligned.

14. Insert the trip pins (32) through the matching holes

in the release ring (35) and cover (8). Make sure that

the tapped hole of the trip pin is inserted first.

15. Slide the release ring (35) counterclockwise so that

the ring engages into the grooves of the trip pins.

16. Insert a spring terminal screw (41) through the other

spring terminal (43) and place a spacer collar (36)

on the end of the screw. Insert the screw into the

tapped hole in the cover and tighten. Repeat this

process for the other return spring .

17. Turn the cover over so that the release ring is facing

down against the surface of the table.

18. Insert the thrust springs (37) into the counterbores of

the cover.

19. Place the trip plate (31) over the cover making sure

that the springs will sit in the counterbores of the trip

plate and that all the holes properly line up.

20. Press down on the trip plate (31) until it stops

against the trip pins.

21. While pressing down on the trip plate (31) insert the

plate mounting screws (42) into the tapped holes of

the trip pins and tighten.

22. Press the cover assembly onto the housing

assembly (1). Make sure that the trunnion holes and

the mounting screw holes line up.

23. Install the cover screws (27) and tighten to the

recommended seating torques shown in Table 10.