Boston Gear • 800-825-6544

P-3003-BG

9

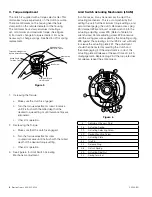

C. Mounting Type “C” Flexible Coupling

1. After the clutch has been mounted on its shaft as

explained in Section lll, inspect the coupling shaft

and key for any nicks or burrs and remove any that

are present.

2. Make sure that the coupling shaft keyway is in

alignment with the clutch shaft keyway. Position

shaft key and slide coupling onto the appropriate

shaft.

3. Slide the coupling flange onto the coupling studs.

The coupling flange and adapter should be

separated by a gap of 1/8”.

4. Secure the coupling to drive shaft by tightening the

two setscrews located in the hub of the flange. Refer

to Table 7 for recommended coupling setscrew

seating torques.

5. Parallel Alignment

a. Place a straightedge across the clutch housing

and coupling flange as shown in Figure 13.

b. Measure the offset around the periphery of these

two components without rotating the shafts.

c. If the difference in offset from any two points

180 degrees apart exceeds the maximum value

shown in Table 8, the shafts must be realigned.

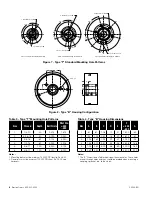

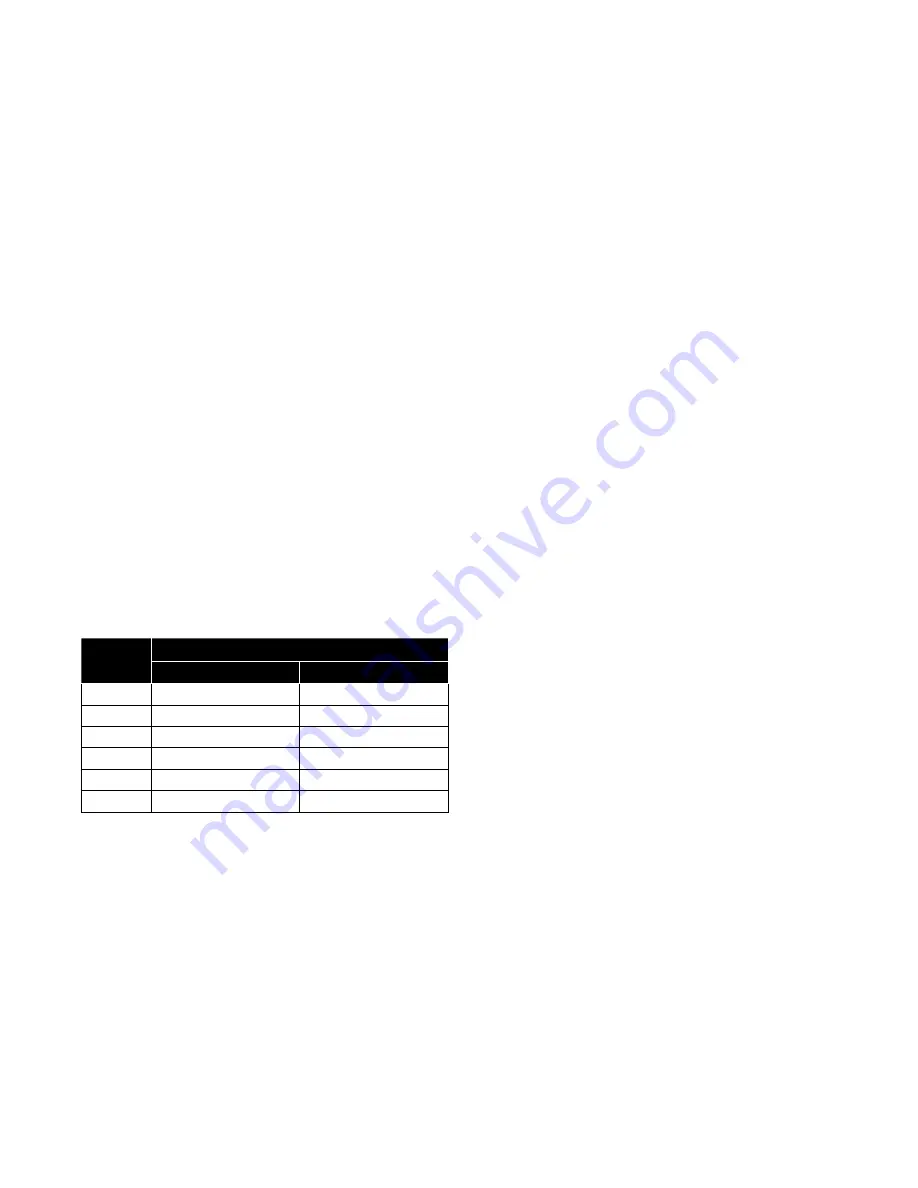

Table 8 - Type “C” Misalignment

Size

Maximum Allowable Misalignment

Parallel

Angular

1

.012”

.074”

2

.015”

.091”

3

.016”

.102”

4

.027”

.159”

5

.031”

.183”

6

.045”

.231”

6. Angular Alignment

a. Measure the gap around the periphery between

the coupling flange and the clutch housing

without rotating the shafts. (See Figure 14).

b. If the difference between any two points 180

degrees apart exceeds the maximum angular

misalignment shown in Table 8, the shafts must

be realigned.

c. If a correction is required to satisfy angular

alignment requirements, then recheck the

parallel alignment.

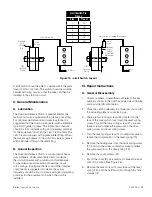

D. Mounting the “N” Index Coupling and Type

“R” Rigid Coupling

1. After the clutch has been mounted on its shaft

as explained in Section lll, inspect mating pilots

of clutch and coupling for any nicks or burrs and

remove any that are present.

2. Inspect coupling shaft and key for any nicks or burrs

and remove any that are present.

3. In the case of a Type “R” make sure that the

coupling shaft keyway is in alignment with the clutch

shaft keyway. Position the shaft key and slide the

coupling flange onto the shaft.

4. Slide the coupling onto the clutch housing making

sure that the coupling pilot fits into the housing pilot

and that the mounting holes are aligned. In the case

of a Type “N” index coupling, make sure that the

desired mounting slots are aligned with the clutch

housing mounting holes.

5. Secure the coupling to the drive shaft by tightening

the two setscrews located in the hub of the flange.

Refer to Table 7 for recommended setscrew seating

torques.

6. Parallel Alignment

a. Place a straightedge across the clutch housing

and coupling flange as shown in Figure 13.

b. Measure the offset around the periphery of these

two components without rotating the shafts.

c. The shafts must be aligned until no offset exists

or is equal at all points around the periphery.