Section 5 • Care & Maintenance

250 Outrage

NOTICE

NEVER use abrasive cleaners, detergents or soft

scrub type cleaners to wash your boats surfaces.

NEVER use abrasive pads, brushes or sponges

to attempt to remove stubborn stains.

NEVER use strong solvents or detergents which

contain chlorine.

NEVER use silver cleaners.

Preventative maintenance is essential to life of the

metals on your boat. The presence of salt particles

and moisture is the major cause of white spots, pitting

and corrosion.

The use of harsh chemicals can also cause deterioration.

Manufacturers and applicators of protective coatings

will not warrant protective coatings on metals in the

marine environment. Proper owner maintenance is

required to reduce deterioration which will result in

most cases by failure to wash down and wipe dry

after each use and/or the use of abrasive, acidic or

other improper cleaners.

Wash completely using a soft cloth and mild

detergent to remove salt particles. Hosing alone will

not dislodge all particles.

DO NOT

allow soap to dry

Aluminum Care

• Dry THOROUGHLY.

• Apply cleaning wax with a soft, dry cloth.

• Allow wax to dry, then polish and buff .

Even the fi nest cleaning powders can scratch or

burnish a mill-rolled surface. On polished fi nishes,

rubbing or wiping should be done in the direction of

the polish lines, NOT across them.

Crevice corrosion, a brownish coloring which occurs

where two pieces of stainless hardware meet is

caused by impurities in water and air. It can be easily

cleaned with a good grade marine polish using a

sponge, cloth or small bristled brush (for nooks and

crannies).

as it may cause stains on coated surfaces. Make sure

to wash and dry the full circumference of aluminum

parts.

Apply an aluminum protectorant at least twice each

year, more frequently as conditions warrant. Neglect

will cause pitting of the surface which cannot be

reversed.

Inspect and repair or replace all damaged nylon

bushings, washers or other hardware designed to

prevent contact with dissimilar metals.

Whenever electrical or electronic changes are made

to the boat, a qualifi ed marine technician should

check aluminum parts for stray currents. Make sure

all electronic equipment is properly grounded with

adequate sized wire.

Cushions

Saltwater, salt residue, dirt, ultra-violet rays etc. will

take their toll on vinyl products causing them to lose

their luster and texture.

The cushions on your boat are made of a durable

vinyl material called OMNOVA which is protected

by a fi nish called PreFixx

®

. PreFixx

®

will keep your

cushions looking new far longer than most other

vinyl upholstery.

To Clean Your Cushions

Solvents are fl ammable. Exercise proper care.

Wear rubber gloves during all cleaning activity.

Use caution when cleaning around buttons,

stitching and wooden or decorative trim as

these solvents could seriously damage such

areas.

CAUTION

•

Remove ordinary dirt and smudges

with a mild

soap and water solution. Dry with a soft, lint-

free cloth or towel.

•

More diffi cult stains

can be cleaned using

rubbing alcohol (isopropyl alcohol).

Rinse cleaned area with fresh water and

Summary of Contents for 250 OUTRAGE

Page 1: ...i R 250 Outrage 250 Outrage ...

Page 2: ...ii R ...

Page 18: ...xviii î ï ð ñ ò ó ô õ ö R ø ù ú û ü ý þ ÿ ú ø ÿ ø ú ý ÿ ø ý ...

Page 42: ...1 24 Ë Ì Í Î Ï Ð Ñ Ò Ó Ô R Õ Ö Ø Ù Ú Û Ü Ý Õ Ü Ý Õ Þ Ý Ú ß ß à ß Ü á Õ â ß Ú Ý ã ...

Page 54: ...2 12 w x y z R ª ª ª ª ª ª ª ª ª µ ª º ª º µ ...

Page 72: ...2 30 µ R º À À Á À Â Ã À Ä ...

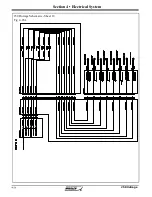

Page 111: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 1 Fig 4 9 1 ...

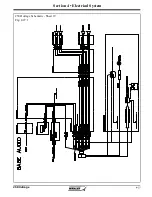

Page 112: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 2 Fig 4 10 1 ...

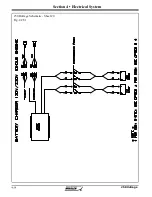

Page 113: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 3 Fig 4 11 1 ...

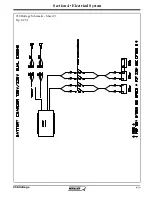

Page 114: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 4 Fig 4 12 1 ...

Page 115: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 5 Fig 4 13 1 ...

Page 116: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 6 Fig 4 14 1 ...

Page 117: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 7 Fig 4 15 1 ...

Page 118: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 8 Fig 4 16 1 ...

Page 119: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 9 Fig 4 17 1 ...

Page 120: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 10 Fig 4 18 1 ...

Page 121: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 11 Fig 4 19 1 ...

Page 122: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 12 Fig 4 20 1 ...

Page 123: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 13 Fig 4 21 1 ...

Page 124: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 14 Fig 4 22 1 ...

Page 125: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 15 Fig 4 23 1 ...

Page 126: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 16 Fig 4 24 1 ...

Page 127: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 17 Fig 4 25 1 ...

Page 128: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 18 Fig 4 26 1 ...

Page 129: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 19 Fig 4 27 1 ...

Page 130: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 20 Fig 4 28 1 ...

Page 131: ...250 Outrage Section 4 Electrical System 250 Outrage Schematic Sheet 21 Fig 4 29 1 ...

Page 132: ...250 Outrage Section 4 Electrical System THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 143: ...Section 5 Care Maintenance 250 Outrage Reinforcement Location Diagram ...