5-11

Section 5

Electrical Systems

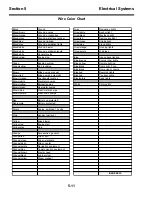

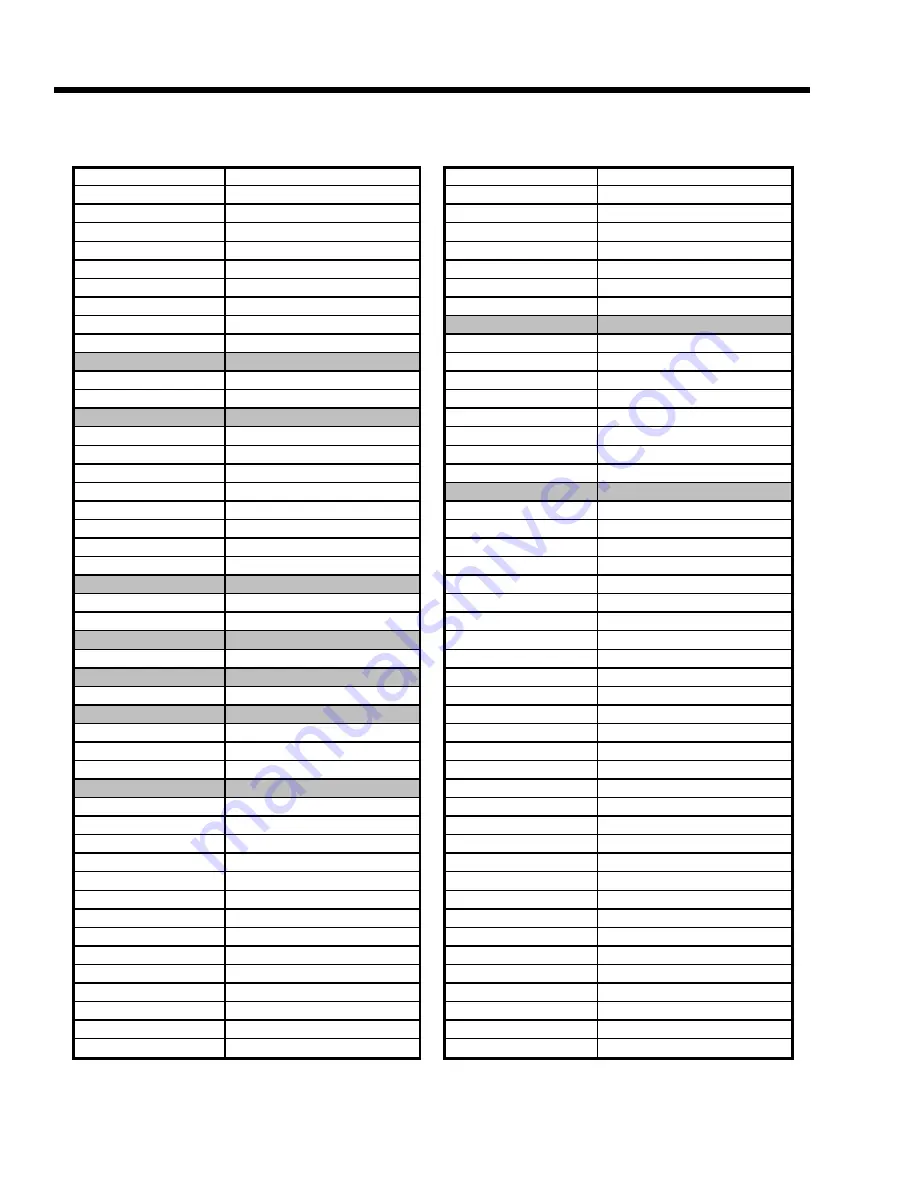

Wire Color Chart

Black

Ground

Gray

Navigation lights

Black/brown

Ground, pumps

Gray/white

Anchor light

Black/orange

Ground, accessories

Gray/black

Masthead light

Black/green

Ground, water level sender

Gray/red

Remote spotlight

Black/blue

Ground, lighting

Gray/green

Strobe light

Black/gray

Ground, navigation lights

Gray/blue

Flood lights

Black/white

Ground, blower

Gray/orange

Docking lights

Black/white

Ground, parallel solenoid

Gray/purple

Windless

Black/white

Generator stop

Black/yellow

Engine stop

Blue

Gauge back lighting

Blue/orange

Engine room lights

Green

Bonding system

Blue/yellow

Remote lighting

Green/yellow

AC grounding

Blue/black

Dome light, T-top

Blue/black

Dome light, console

Brown

Bilge pumps, manual

Blue/red

Boarding lights

Brown/red

Bilge pumps, automatic

Blue/red

Courtesy lights

Brown/orange

Fuel transfer pumps

Blue/purple

Deck lights

Brown/white

Macerator pumps

Brown/yellow

Baitwell pumps

White

CO monitor

Brown/green

Raw water pumps

Brown/blue

Fresh water pumps

Brown/purple

Washdown pumps

Red

Battery, unprotected

Red/purple

Battery, protected

Purple

Engine, switched 12 volts

Pink

Sender, fuel level

Yellow

Bilge blower

Yellow/red

Engine start

Yellow/gray

Horn

Orange

Accessories, general

Orange/red

Wiper, port

Orange/green

Wiper, starboard

Orange/white

Wiper, center

Orange/purple

Navigation equipment

Orange/blue

Communication equipment

Orange/brown

Electric head

Orange/black

Audio system

Orange/yellow

Diesel preheat

BCGP 2013

Summary of Contents for Boston Whaler 15 Guardian Series

Page 16: ...1 8 Section 1 Safety Deck Occupancy Chart...

Page 18: ...1 10 Section 1 Safety Warning Label Chart 1 2 4 3 5 6 7 8 9 0 A...

Page 20: ...1 12 Operator Notes...

Page 74: ...5 12 Operator Notes...

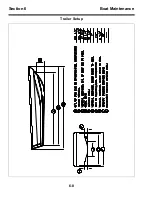

Page 82: ...6 8 Section 6 Boat Maintenance Trailer Setup...

Page 90: ...6 16 Operator Notes...