3-15

345 Conquest

Section 3 • Systems & Components Overview & Operation

Section 3 • Systems & Components Overview & Operation

345 Conquest

R

Section 3 • Systems & Components Overview & Operation

Tempering Valve

A tempering valve is installed on the hot water outlet

of the water heater (Fig. 3.16.1) to reduce the risk of

scalding. The valve is set at it’s lowest temperature

(100°F) at the factory. The water temperature can be

adjusted up to a maximum of 130°F by turning the

valve counterclockwise until the water temperature

reaches your desired limit.

REFER TO THE MANUFACTURER’S MANUAL IN

YOUR OWNER’S MANUAL PACKET FOR COMPLETE

INSTRUCTIONS AND WARRANTY.

Fresh Water System Maintenance

Very little maintenance

is required for the fresh

water system, other than

annual disinfecting and

winterizing. Periodically

check the entire system

to assure that the hose

connections, tube fittings,

electrical connections and

mounting bolts are properly secured, and free of

chafing.

Periodically check the in-line strainer attached to the

pump, and clean if necessary.

The system should be run at least every other month

to maintain the pump’s impellers in a stable operating

condition.

Maintenance

The water heater connections will need to be

inspected regularily. Access to the water heater can be

made through the back wall of the hanging closet in

the forward console. If you notice any leaks around

the water heater call your dealer.

Manually operate the pressure relief valve at least

once a year. This must be done when the water in

the storage tank is cool.

The system must be flushed several times per year;

which will prolong the life of the system. There may

be times that you will notice an odor coming from the

water system. There is a protective cladding in the tank

that protects it from corrosion. The electro-galvanic

action of the cladding material releases hydrogen

from the water. If sulfur or any of its combinations

are present in the water the two will combine and

produce hydrogen sulfide. This compound will

produce a “Rotten Egg Odor”. Hydrogen sulfide can

also be present in your freshwater supply. It is the

product of the decay of animal matter and as little as

1 mg/liter can cause a perceptible odor.

Make certain that the system is completely drained

before laying up for the winter season. The freshwater

tank will have to be drained and flushed with a non-

toxic anti-freeze before winter storage.

If equipped, the engine flushing system is fully

automatic and flushes salt and minerals from

the internal components of marine engines more

effectively and conveniently than conventional

methods.

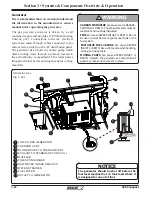

Operation

• Attach a water hose to the fresh water intake

located on the port transom (Figure 3.14.1).

Automatic Engine Flushing System

(Option)

ENG FLUSH

OPERATION

FULL CYCLE (15 MIN/ENG):

PRESS ONCE TO START

PRESS TWICE TO STOP

HALF CYCLE (7.5 MIN/ENT):

PRESS TWICE TO START

PRESS ONCE TO STOP

Engine Flush System (Option)

Fig. 3.15.1

1

2

ENGINE FLUSH PANEL

FRESH WATER INTAKE

1

2

Summary of Contents for CONQUEST 345

Page 21: ...xix 345 Conquest THIS PAGE INTENTIONALLY LEFT BLANK...

Page 93: ...2 46 Section 2 General Information 345 Conquest THIS PAGE INTENTIONALLY LEFT BLANK...

Page 150: ...4 16 345 Conquest Section 4 Electrical System Batteries Joystick Steering Option Fig 4 16 1...

Page 152: ...4 18 345 Conquest Section 4 Electrical System DC MDP Joystick Steering Fig 4 18 1...

Page 154: ...4 20 345 Conquest Section 4 Electrical System AC Power 220V 50Hz Fig 4 20 1...

Page 156: ...4 22 345 Conquest Section 4 Electrical System Cabin O H and Accent Lights Fig 4 22 1...

Page 158: ...4 24 345 Conquest Section 4 Electrical System Wipers and Washers Fig 4 24 1...

Page 160: ...4 26 345 Conquest Section 4 Electrical System Waste System Fig 4 26 1...

Page 161: ...4 27 Section 4 Electrical System 345 Conquest Section 4 Electrical System Windlass Fig 4 27 1...

Page 162: ...4 28 345 Conquest Section 4 Electrical System Trim Tabs Fig 4 28 1...

Page 166: ...4 32 345 Conquest Section 4 Electrical System Pumps Sheet 2 Fig 4 32 1...

Page 168: ...4 34 345 Conquest Section 4 Electrical System V Berth Schematic Fig 4 34 1...

Page 170: ...4 36 345 Conquest Section 4 Electrical System Shore Power 230V 50HZ Fig 4 36 1...

Page 172: ...4 38 345 Conquest Section 4 Electrical System Stereo Premium Option Fig 4 38 1...

Page 174: ...4 40 345 Conquest Section 4 Electrical System Heater CO Monitor Fig 4 40 1...

Page 176: ...4 42 345 Conquest Section 4 Electrical System Generator 230V 50Hz Fig 4 42 1...

Page 178: ...4 44 345 Conquest Section 4 Electrical System STBD AC Harness Fig 4 42 1...

Page 180: ...4 46 345 Conquest Section 4 Electrical System STBD DC Harness Fig 4 44 1...

Page 182: ...4 48 345 Conquest Section 4 Electrical System Windlass Harness Fig 4 46 1...

Page 206: ...5 22 Section 5 Care Maintenance 345 Conquest THIS PAGE INTENTIONALLY LEFT BLANK...