8

3. Security Regulations

3.1 Identification of safety

instructions

GARDNER DENVER accepts no

responsibility for any damage or injury

caused by non-compliance with these

safety measures or non-observance of

normal care and caution during the

handling, operation, maintenance or repair

of this compressor, even if not expressly

stated in this operating manual.

If any of the regulations contained in

this manual do not correspond to local

statutory provisions, particularly with

reference to safety, then the stricter of

the two applies.

These safety instructions are of a

general nature and are applicable to

various types of machine and equipment.

For this reason it is possible that some

information may not apply to the

aggregate(s) described in this manual.

Danger

Places thus marked refer to possible

dangers for persons.

Attention

Places thus marked refer to possible

dangers for machines or parts of

machines.

Places thus marked give general and

technical information for optimum, cost-

effective machine use.

3.2 General safety instructions

Organizational measures

Please keep this operating manual

handy at all times on the site of the

machine / installation, in the bag provided.

Please note and pass on general

statutory and other binding regulations

that may supplement the operating

manual for the prevention of accidents

and the protection of the environment.

Such obligations may be for example the

handling of hazardous materials, or the

provision and/or wearing of personal

working. This applies particularly to

personnel only using the machine

occasionally, e.g. for setting up and

maintaining the machine.

Safety and danger-conscious working

by the personnel in compliance with the

operating manual should be checked at

least occasionally.

The personnel must not have long, loose

hair, or wear loose clothing or jewellery,

including rings, due to risk of injury

through catching. Personal protective

equipment should be worn if necessary or

as required by regulations.

Pay attention to all safety and danger

warnings on the machine/ installation!

Make sure that all safety and danger

warnings on the machine / installation can

be read.

For all safety-relevant modifications to

the machine / installation or its operating

behavior, stop the machine / installation

immediately and report the fault to the

competent authority / person.

Spare parts must meet the technical

requirements laid down by the

manufacturer. This is always guaranteed

when original spare parts are used.

Replace hydraulic hoses at the given

intervals, or at suitable intervals, even if

no safety-relevant defects are visible

(DIN 20066, Part 5).

Observe the intervals stipulated or those

given in the operating manual for routine

checks and inspections.

Workshop equipment suitable for

carrying out maintenance work is

essential.

The location and operation of fire

extinguishers must be made known.

Observe the instructions concerning fire

alarm and fire fighting.

Limiting values (pressure, temperature,

time settings etc.) must be permanently

marked.

Personnel selection and

qualification; basic tasks

Work on or with the machine /

Define who is responsible for operating

the machine, and authorize him to ignore

instructions from third parties if these

instructions could compromise safety.

Only allow personnel that are training,

that are under instruction or are attending

a course of general training to use the

machine / installation under the constant

supervision of an experienced person.

Work on the electrical systems of the

machine / installation may only be carried

out by a trained electrician in accordance

with electrical regulations.

Only persons with special knowledge

and experience of hydraulics may work on

system elements, for example

components under pressure.

3.3 Modifications and alterations

to the machine

No alterations, additions, or

modifications to the machine may be

carried out without the approval of the

manufacturer. This is also true for the

installation and the adjustment of safety

devices and valves as well as for welding

at supporting and pressurized parts.

Unauthorized modifications to the machine

are prohibited for reasons of safety.

Original parts are specially designed for

our machines. We must explicitly point out

that parts and special accessories not

supplied by us are not approved by us.

Installing or using such products may thus

adversely aff ect active and/or passive

safety.

The manufacturer accepts no liability

whatsoever for damage resulting from the

use of non-original parts or special

accessories. This also applies to the

installation and adjustment of safety

devices and valves as well as to welding

on bearing and pressurized parts.

Note

The General Type Approval becomes

invalid in case of modifications or

alterations which change or infringe upon

the external geometry as well as the gross

axle weight rating.

protective equipment, or traffic regulations.

installation may only be carried out by

Instructions, including supervisory

responsibility and duty of notification for

taking account of special in-plant factors,

for example regarding work organization,

sequences of operations, personnel

assigned to certain tasks, are to be added

to the operating manual.

Personnel delegated to work with the

machine must have read the operating

manual before beginning this work,

particularly the chapter on safety

instructions. It is too late to do this while

reliable personnel. Observe the minimum

statutory age.

Only trained or specially instructed

personnel may be assigned to this work.

The responsibility of the personnel for

operating, setting up, maintaining and

repairing the machine / installation must

be clearly defined.

Make sure that only authorized

personnel use the machine.

3.4 Loading/Relocation/Transport

Loading / Relocation

All loose parts that could fall down when

the machine is lifted must first be removed or

secured; pivoting parts like doors, etc.

must be immobilized.

For lifting heavy parts, hoisting gear and

heavy-lift facilities with the appropriate

capacities, which have been checked and

approved in accordance with local safety

regulations, must be used.

Note

Summary of Contents for GDP21

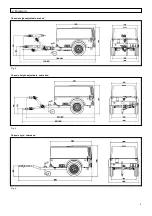

Page 8: ...6 2 Foreword Chassis rigid braked Fig 5...

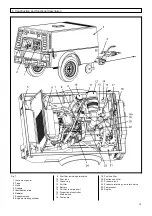

Page 53: ......

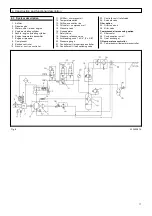

Page 61: ......

Page 62: ......