5. Transport and installation on site

20

5.1 Transport

Transport safety locking of the towing

arrangement

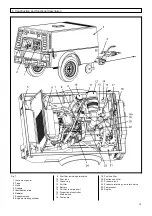

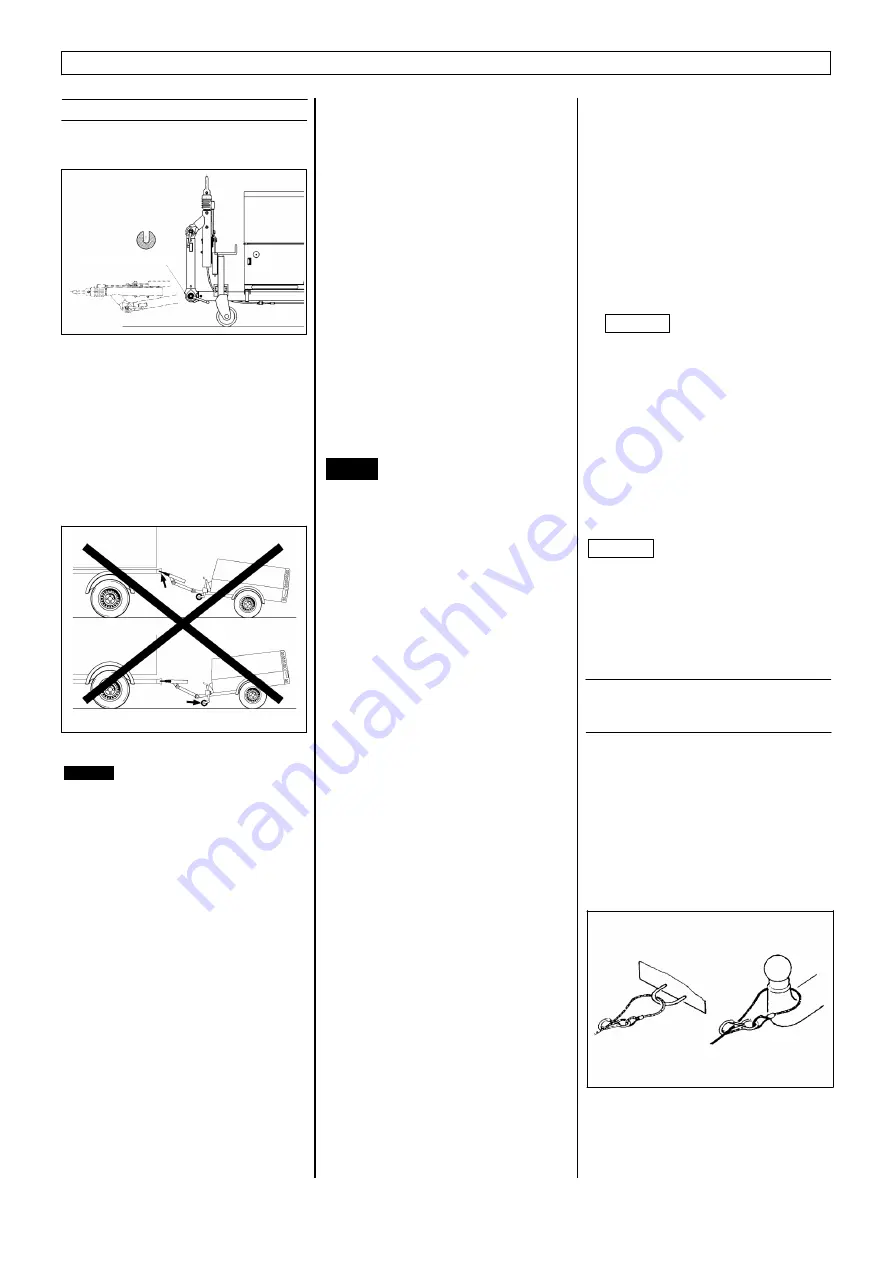

Fig. 11

Before moving the compressor for the

first time slacken the ratchet on height-

adjustable towing gear and remove the

transport securement. Then adjust the

towing gear from the vertical transport

position to the required attachment height

for the towing vehicle and lock it in place

in the toothing using the ratchet (see

Section 15. Undercarriage, height-

adjustable towing gear).

Fig. 12

Danger

Make sure to check the torque after

50 kilometers following wheel

mounting and at regular intervals.

Tighten wheel nuts or screws evenly

in a diagonal sequence to the specified

torque using a torque wrench.

Replacing the trailer coupling ring

The coupling arrangements which can

be used:

*

Trailer coupling ring RD 40

*

Coupling 50 dia.

*

Coupling ring 2" dia. (only for UK)

*

Coupling ring 68 x 25 dia. (only for

France)

A different coupling unit in the form of a

complete kit may be ordered, if necessary.

Replacing the trailer coupling ring is

permitted only if proper fitting is carried out

by an inspectorate for the sector covered

by the Regulations Authorizing the Use of

Vehicles for Road Traffic (e.G. the TÜV -

Technical Inspectorate, DEKRA - German

Motor Vehicle Monitoring Association,

etc.). The inspection station provides a

fitting certificate to be kept with the vehicle

documents.

The screw compressor may only

be transported on public roads if

*

The machine group (engine) is

not running,

*

The pressure tank is not under

pressure,

*

The shielding is closed,

*

The blocks are firmly hooked in

place,

*

Hoisted and secured tail wheel,

*

The tyres and brakes are

operationally safe and roadworthy,

*

The lighting is fully functional.

Never exceed the maximum towing

speed! Danger! Observe national

regulations!

Please also observe the safety

instructions in Chapter 3 on the

subject of transporting.

Before transporting the compressor,

check to make sure that the draw gear of

the towing vehicle and the drawbar eye or

trailer hitch ball connection are aligned

exactly to each other.

When transporting the screw compressor

with a vehicle, the following points must

be observed:

*

The shielding is closed.

*

The blocks are firmly hooked in place.

*

The support(s) is(are) retracted and

locked in position (jockey wheel).

*

Drawbar is connected to the towing

vehicle.

*

The drawbar is adjusted to the height

of the towing vehicle (option).

*

The contact-breaking cable is

connected to the towing vehicle. Safety

chains are attached on towing vehicle.

*

The electrical cable (option) is

connected to the vehicle and to the

screw compressor .

*

Check the lights (tail lights, brake

lights, indicator lights, and rear fog

lamp) (option).

*

Check to make sure that the wheels

are properly tightened, the tyres are in

a roadworthy condition.

Check tyre pressure, and adjust if

necessary (risk of accident). A too

high tyre pressure can lead to

overstraining of safety parts.

*

When parking the compressor prior to

uncoupling from the towing vehicle

actuate the handbrake, detach the

contact-breaker cable and the lighting

cable, and secure the compressor

against rolling using chocks. Then

adjust to the horizontal position by

means of a support or support wheel.

Always keep a safe distance from the

edges of foundation ditches and

embankments! Do not travel across

slopes transversely.

5.2 Attachment of the contact-

breaker cable on braked

chassis

If the towing connection becomes

uncoupled, the trailer is braked by the

breakaway cable. Put the breakaway cable

in the eye provided or wind it around the

towing collar and hitch it up to the cable

with the snap link.

The breakaway cable must be attached

in a way that ensures that even on

extremely sharp bends there is no danger

of activating the locking brake.

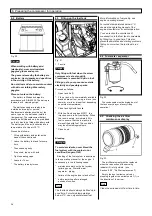

Fig. 13

Danger

Attention

Attention

Transport safety locking

Summary of Contents for GDP21

Page 8: ...6 2 Foreword Chassis rigid braked Fig 5...

Page 53: ......

Page 61: ......

Page 62: ......