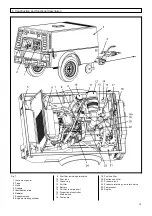

5. Transport and installation on site

22

The screw compressor is to be set up

in such a way that no air reflection can

take place, i.e. neither waste air nor

exhaust emissions may be drawn in;

the same applies to dangerous

admixtures to the air. Drawing this

waste air in could lead to overheating

and a loss of power.

The compressor must be set up in as

horizontal a position as possible.

Maximum permissible inclination during

operation:

* In direction of pull: 15 degrees

* Backwards: 15 degrees

*

To the right and to the left: 15 degrees

Fig. 16

Greater inclinations endanger the

operating reliability of the screw

compressor.

When setting up the unit on ground that

is not horizontal, or with a variable angle

(see operating instructions) please consult

GARDNER DENVER.

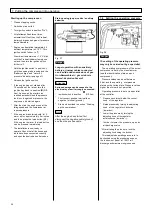

Set up the machine in such a way that

no inlets, outlets or gates are blocked,

even when the doors are open. Prior to

uncoupling from the tow vehicle actuate

the handbrake, detach the contact-breaker

cable and the lighting cable, and secure

the compressor against rolling using

chocks. Then adjust to the horizontal

position by means of a support or support

wheel.

No force may be exerted on the dis-

charge valves, for example by pulling

the hoses or fitting additional

equipment (e.g. a water separator,

compressed air oiler, etc.) directly at

the discharge valve.

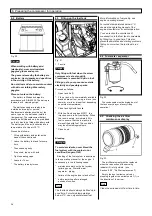

Temperatures/air humidity

Install the compressor in a location with

maximum possible frost protection. The

suction air temperature must be within the

range specified on the data

An oil-temperature regulator (option) is

necessary for operation of the system

at high temperatures (+40° C and

above) and/or high rel. air humidity

(greater than 90 %) or at temperatures

below 0°C. For operation involving

long periods of idling and/or low partial

loads an oil temperature regulator is

also required.

Altitude

For operation at an altitude above

1,000 m, the compressor and engine must

be adapted (modified design).

Note

Particularly in case of installation out of

doors and at night, observe fuel tempera-

ture. At temperatures below 0 °C, summer

diesel fuel tends to precipitate and block

the fuel filter. In this case use winter diesel

fuel.

In dusty environments, set up the machine

in such a way that the wind does not blow

the dust in the direction of the machine.

During operation in clean environments,

the intervals for cleaning the air intake

filter and the cooler elements are much

longer.

Note

Attention

Attention

Attention

Attention

Summary of Contents for GDP21

Page 8: ...6 2 Foreword Chassis rigid braked Fig 5...

Page 53: ......

Page 61: ......

Page 62: ......