25

7. Putting the compressor into operation

7.1 Initial operation

Transport inspection

Every GARDNER DENVER screw

compressor has already run in the factory

and has already undergone a thorough

test before shipment. This test ensures

that the compressor complies with the

given data and works perfectly.

Independent of the care taken in the

factory, it is still possible for the

compressor to be damaged during

transport. For this reason it is

recommended that the unit should be

examined for possible damage during

transport.

Remove any transport seals (dummy

flange, plugs, etc.) and dehydrating

agents before start-up. Distribution tubes

and connection lines must have the

specified dimensions and must be suitable

for use with the max. operating pressure

and the media to be taken up.

During the first hours of operation, the

compressor should be observed in order

to be able to ascertain any possible

malfunctions.

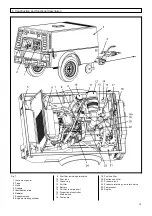

7.2 Operating elements

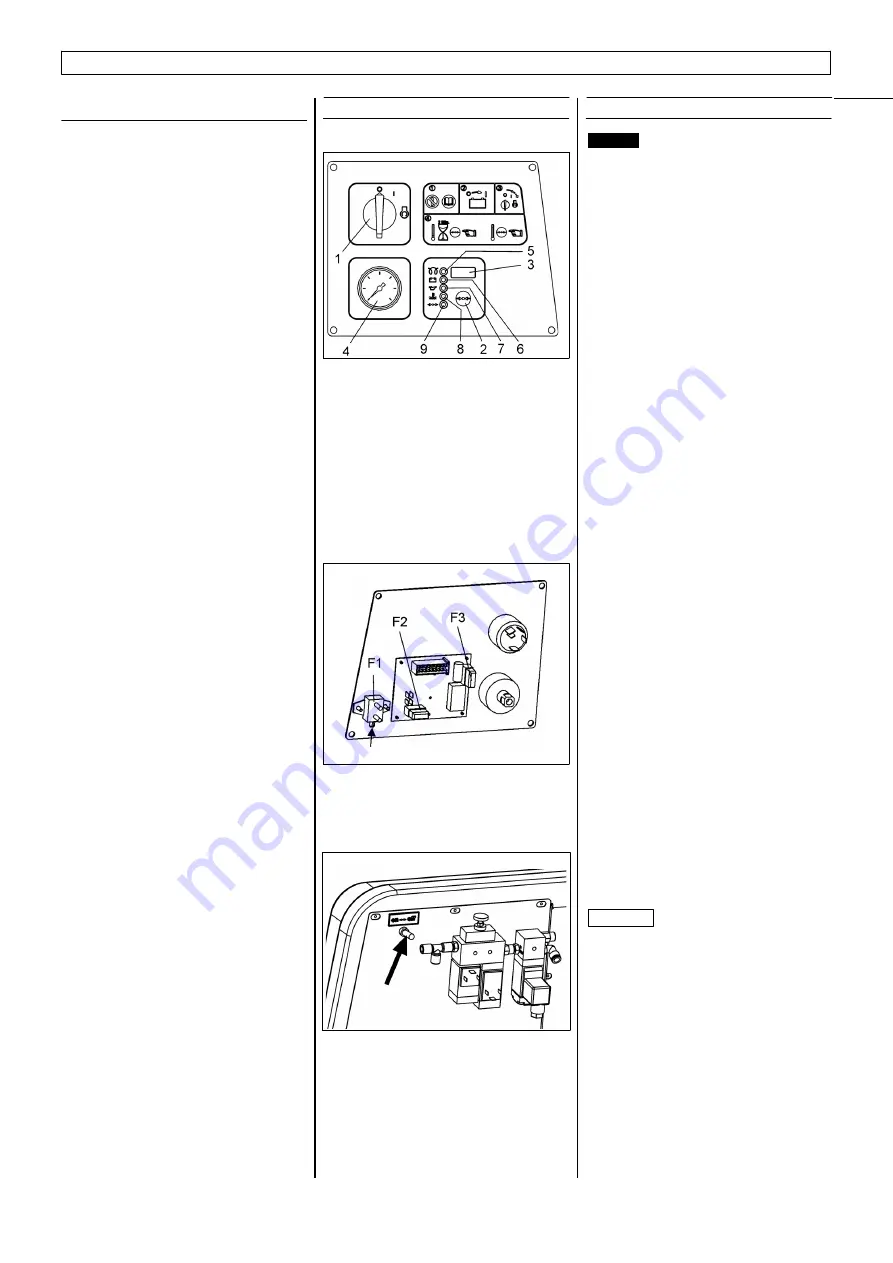

Operating panel:

Fig. 24

1 Ignition switch

2 Load button

3

Hours of operation counter

4

Operating pressure gauge

5

LED 1 Pre-heating

6 LED 2 Battery charge

7 LED 3 steady => Oil pressure

flashing=> Fuel shortage

8

LED 4 Motor and compressor

temperature

9

LED 5 Load run

Fig. 25

F1 Main fuse

F2 Fuel pump

F3 Lifting magnet

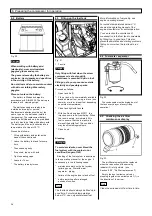

7.3 Start-up

Danger

Before starting up, make sure that no

one is in the danger area of the engine

/ screw compressor.

Compressors may not be operated in

hazardous environments unless they

have been specially designed for this

purpose (e.g. exhaust protected

against emission of flying sparks etc.).

Never, under any circumstances, use

"Startpilot" (Spray-can starting aid),

ether or other starting aids - Danger of

explosion!

After service work has been completed:

Make sure that all protective devices

have been refitted and that all tools

have been removed.

The exhaust from the system

contains carbon monoxide, a lethal

gas.

The exhaust must be routed to the

outside via a pipe or a hose with an

internal diameter of not less than

100 mm if the compressor is used

indoors.

Adequate ventilation must be

assured.

The use of an exhauster system is

urgently recommended.

Only operate the compressor with the

hood closed. The hood may only be

opened briefly for minor adjustments

while the compressor is running.

Skilled personnel only are authorized

to work with the hood open.

When working with the screw

compressor in operation and with the

shielding/hood open, wear ear

protection.

Caution: this may impair

communication between persons.

Warnings may not be heard. Inform

supervisor.

Fig. 26 Main switch

Opening the covering interferes with

the flow of cool air in the compressor

section.

Full sound-insulating is only achieved

when the covering is closed.

Check the oil levels in the pressure

tank and in the engine of the

compressor each time before start-up.

Do not start the compressor unless the

air tapping cocks are closed.

Attention

Summary of Contents for GDP21

Page 8: ...6 2 Foreword Chassis rigid braked Fig 5...

Page 53: ......

Page 61: ......

Page 62: ......