Dari-Kool III-120 Instructions

3

1E-138B

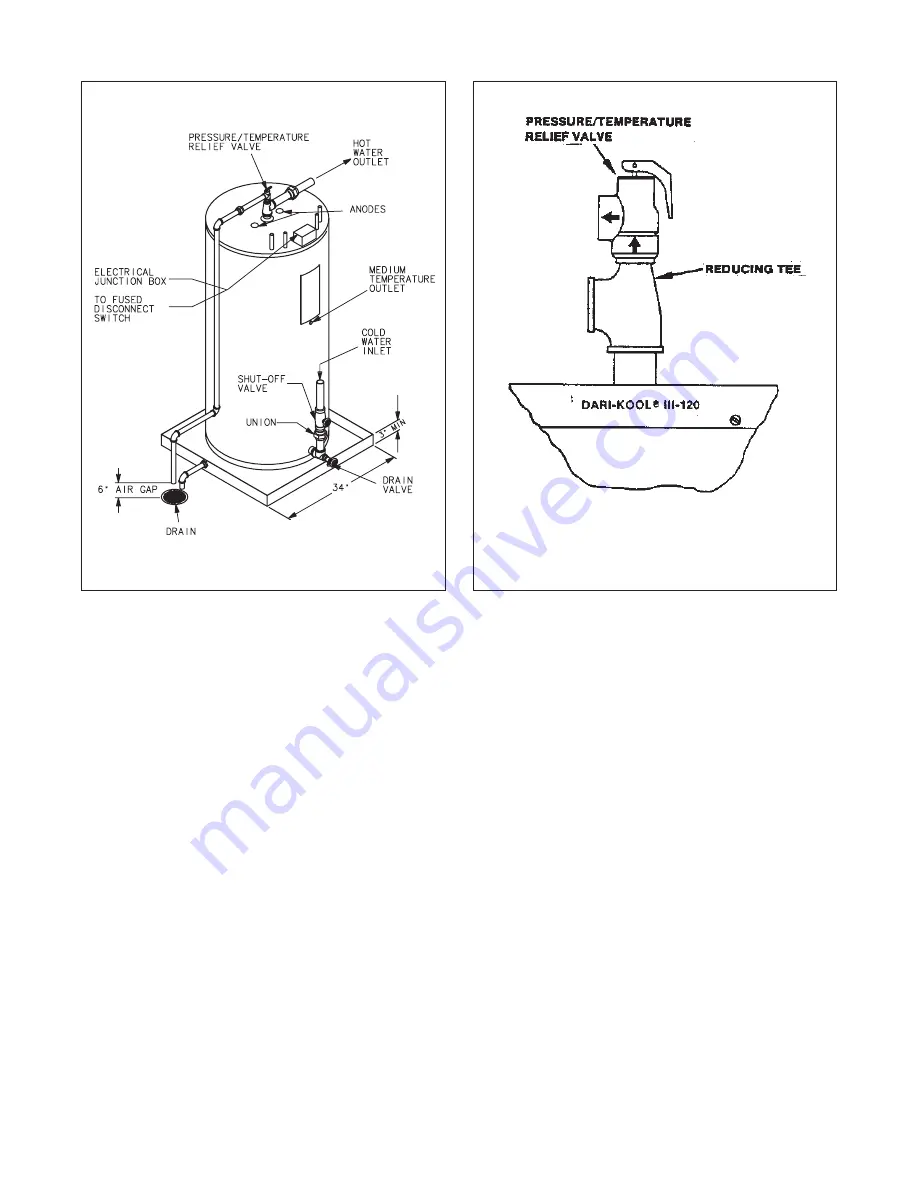

Figure 1. Dari-Kool III-120 Plumbing l138_1

Figure 2. Pressure/Temperature Relief Valve Installation

Important Note: A temperature and pressure relief valve is for

protection against both excessive temperature and pressure; and

if either of these conditions develop in the system, the valve will

open and discharge water. ( label P/N 4016124)

4. The optional water valve limits the water temperature when

refrigerant heat input is too high. It should be installed to bleed

water to the drain or to a suitable alternate point of usage such

as a heat exchanger or reservoir. This normally-open valve is

closed only when energized, so it will be open when the water

in the Dari-Kool III-120 reaches the thermostatic set point. It

will also be open if a power outage occurs. Considerations

should be made to accommodate a flow rate of 40 gallons

(151 L) per hour. See Figure 3 for the preferred installation.

See the electrical section for wiring instructions.

5. To fill the Dari-Kool III-120: Close the drain valve and open a

hot water tap to bleed the air from the tank as it fills. Open

the inlet water valve. Allow sufficient time for the tank to fill,

as indicated by a steady flow of water, then close the water

tap and check for leaks.

6. If the solenoid water valve is used, power will have to be

applied to the valve in order to close it while checking

for leaks. DO NOT apply power to the heating element unless

it is covered with water.

7. The Dari-Kool III-120 has dual magnesium anode protection.

Under certain water conditions, an offensive odor may be

noticed after the system is in operation. To eliminate this odor,

remove the magnesium anodes and install aluminum anodes

(Part No. 4016425).

— Note ———————————————————————

ALTERNATE PRESSURE/TEMPERATURE RELIEF VALVE.

In the event that the combination pressure/temperature relief valve

is lost or damaged, an alternate device may be used providing it:

•

has a minimum thermal rating of 100,000 BTUH (3 kW hours)

•

has a maximum pressure rating of 150 PSIG (1000 kPa)

•

is certified as meeting the requirements of ANSI Z231.22, by a

nationally recognized testing laboratory.

4.

Installing the Refrigeration System

4.1

Installation Layout

The Dari-Kool III-120 is designed for use in refrigeration

systems that have adequately-sized air-or water-cooled

condensors. The Dari-Kool III-120 should be installed

between the compressor and condensor. A number of possible

combinations are shown in Figures 6-12.

— Note ———————————————————————

Capillary tube systems are not normally recommended for use

with Dari-Kool. For special considerations, please contact the

factory.

4.2

Refrigerant

The Dari-Kool III-120 desuperheater plate is designed for

low pressure drop. Each of the two sections of the plate will

handle up to 7.5 tons (26 kW) of R-22, R-404, R-407, or 5

tons (17.5 kW) of R-134A.