1E-138B

4

Dari-Kool III-120 Instructions

1. If cabinet openings or modifications have to be made,

they must be accomplished in such a manner as not to

be detrimental to the cabinet. Do not cut into electrical

enclosures.

2. Do not route tubing through electrical enclosures or cabinet

sections containing live metal parts. The tubing

must be properly supported and protected from sharp edges

and moving parts.

3. The tubing must be mechanically isolated from structural

building members.

— Note ———————————————————————

• Be careful not to burn wrapper on insulation when brazing

refrigeration lines.

• All joints should be checked for leaks and the lines evacuated

according to standard refrigeration practices.

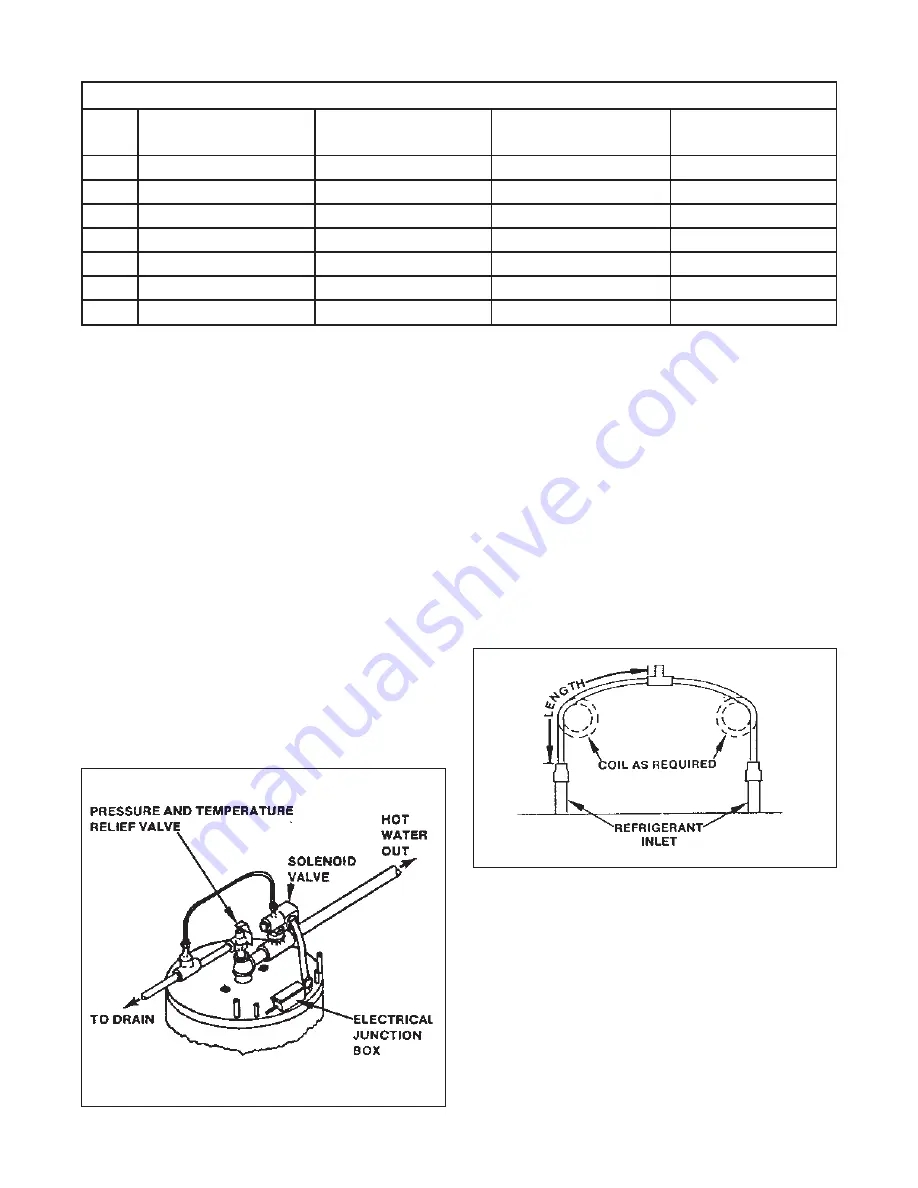

Figure 3. Water Valve Installation

4.3

Refrigerant Lines

The compressor discharge line size is usually adequate for

normal installations. However, if lines are more than 20 feet

(6 m) long, they should be sized for a maximum of 15 PSIG

(103 kPa) pressure drop. (See ASHREA piping tables.) Lines

should be installed to pitch toward the Dari-Kool III-120 and

condensor, and to drop down from the compressor discharge

to form a 6” (152 mm) trap to prevent oil and liquid refrigerant

from accumulating on the discharge valve plate.

When two circuits of the Dari-Kool III-120 are connected to

a single compressor, it is important to size the inlet tubes to

create a small but equal pressure drop. This small pressure drop

is required to insure equal distribution through each circuit.

This is important to achieve optimum performance, and to

prevent oil and liquid trapping. See the following table for

recommended line sizes. These diameters and lengths should

create about a 5 PSI (34 kPa) pressure drop.

When installing a Dari-Kool III-120 on an existing refrigeration

installation, extreme care must be used not to damage the

existing system. If the tubing must be routed into an existing

cabinet, the following precautions must be taken:

Figure 4. Manifold for single compressor Installation on inlets only.

Table 1: Recommended Line Sizes

HP

R-134A Dia.

Length

R-22 Dia.

Length

2

1/4” (6 mm)

12' (4 m)

1/4' (6 mm)

36' (11 m)

3

5/16” (8 mm)

28' (9 m)

1/4' (6 mm)

12' (4 m)

4

5/16” (8 mm)

12' (4 m)

5/16' (8 mm)

36' (11 m)

5

3/8” (10 mm)

30' (9 m)

5/16' (8 mm)

20' (6 m)

6

3/8” (10 mm)

24' (7 m)

−

−

7-1/2

3/8” (10 mm)

12' (4 m)

3/8' (10 mm)

36' (11 m)

10

−

−

3/8' (10 mm)

12' (4 m)