Page 6

9e1048

1.4 SUCCESSFUL MILKING

Prerequisites for successful milking:

• A milking installation designed in accordance with ISO 5707 or 3 A and set up correctly.

• Stable vacuum conditions due to an appropriately sized vacuum pump, a balance tank and vacuum

reserve as well as properly sized vacuum lines.

• Milking vacuum and automatic cluster removal must be set correctly to suit the animals.

Regular checks and adjustments to meet any herd changes will also ensure successful milking.

• A milking cluster selected to suit the animals.

• Correctly positioned cluster. Keep hoses as short as possible to avoid unnecessary sagging.

• Scheduled maintenance and cleaning of the milking installation. Regular thorough cleaning and

disinfection of the milking installation will help improve animal health, milk quality and therefore milking

results.

• When replacing parts, only use genuine BouMatic spare parts!

• Recommended settings are only valid in conjunction with genuine BouMatic products.

• The conscientious implementation of milking routines will have a positive effect on milking results.

Attention!

Milking without milk flow (overmilking) must be avoided, as it will very quickly have an adverse

effect on teat condition and udder health

Rub to

remove any

residual

bedding.

Dip with

pre-dip.

Strip/wash

teat end

with

gloved hand.

Dry with

one circular

motion - flip

towel and

aggressively

squeeze

teat end.

Attach

unit.

Adjust unit

for proper

placement.

Post-dip -

cover

complete

teat!!

10 to 12 seconds of teat contact

time. (stripping, washing and

drying)

Attach unit

within 75-90

seconds after

steps 3 and 4.

After attachment, adjust unit to

hang squarely on the cow as soon

as the last teat cup is attached.

Gently,

Quickly and

Completely

Always Milk Your Cows...

7 Step Udder Prep

BouMatic.com

1

2

3

4

5

6

7

Summary of Contents for Xcalibur

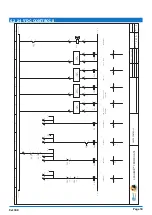

Page 31: ...Page 31 9e1048 8 24 CONTROL BOX Relay Power Supply c...

Page 32: ...Page 32 9e1048...

Page 33: ......