71

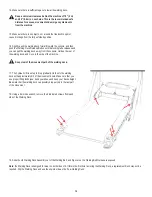

9. Using a #2 Phillips screwdriver, remove the 3 screws (indicated by

arrows) that secure the Right-Inside Deck Shroud. Remove it from the

machine.

10. Using a #2 Phillips screwdriver, remove the 10 screws (indicated by

arrows) that secure the Right-Front and Right-Rear Deck Suspensions to

the Walking Deck.

Deck Shroud, Right-Inside

Deck Suspension,

Right-Rear

Deck Suspension,

Right-Front

Summary of Contents for Treadmill 22

Page 28: ...28 ELECTRICAL WIRING ...