Rev D

10

6 Potential Service Issues

6.1 Tube failures

The majority of problems facing a heat exchanger are those of corrosion or erosion on the water side.

Three common types of failure are:

a) Impingement attack (or corrosion/erosion)

This is caused by water containing air bubbles flowing at high speed through the tubes. The

impingement of rapidly moving water may lead to a breakdown of the protective copper oxide film built

up by the tube thus allowing corrosion/erosion. This is worse with water containing sand or grit. The

effect of these conditions would be pockmarking and pinholing of the tubes.

b) Oxide corrosion

This is caused by water containing organic matter such as that found in polluted estuaries. Usually this

water produces hydrogen sulphide, which is very corrosive and can cause failure of the tubes,

particularly if excessive water flows are used

c) Pitting

This problem is caused by very aggressive sea water in the tubes, especially in partially filled coolers

where the sea water is stagnant. Low sea water flow rates can create a high temperature rise on the sea

water side. Under these conditions deposits may build or settle in the tube, allowing pitting corrosion to

take place under the deposits.

This is only a brief introduction to corrosion problems. The subject is complex and the purpose of

these notes is to outline in very general terms what may occur under extreme conditions.

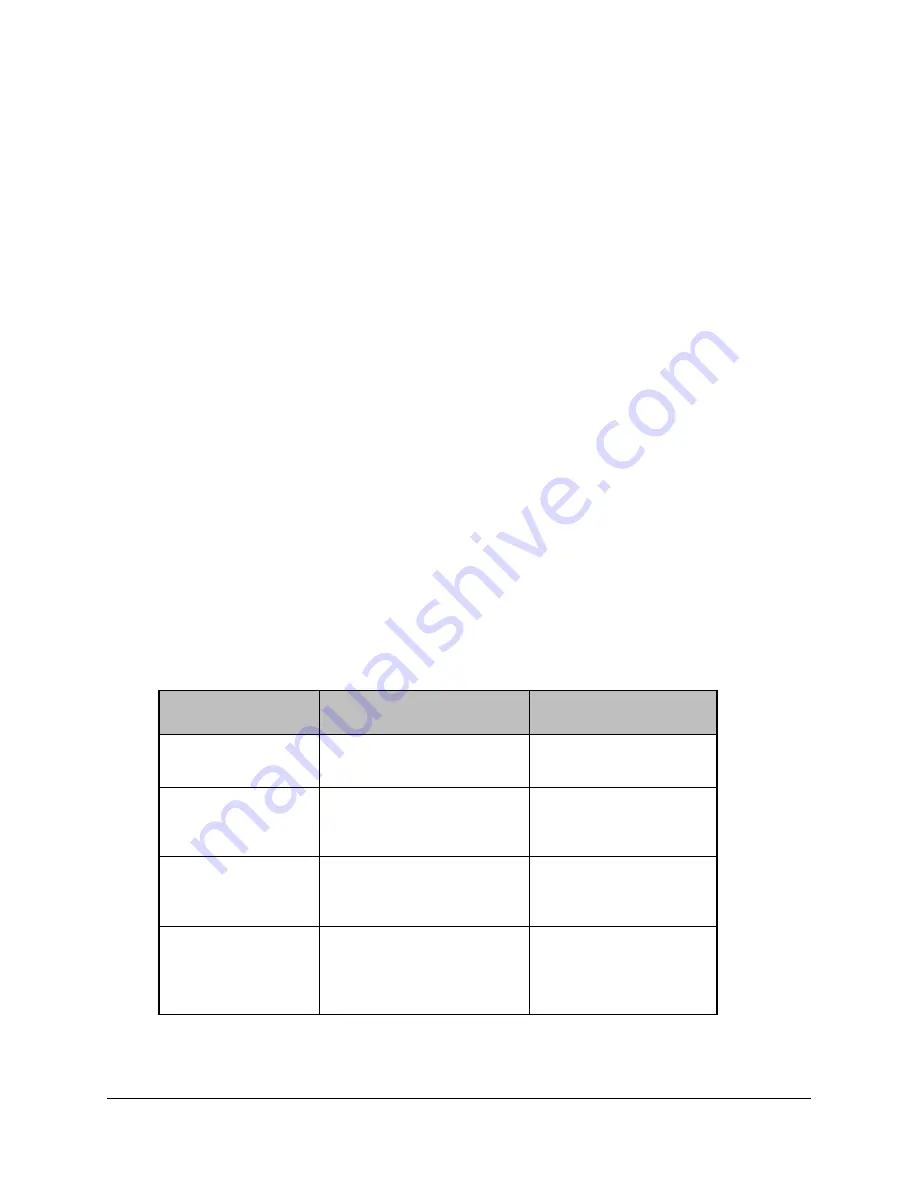

6.2 Fault finding

Symptoms

Possible Causes

Remedy

Increase in temperature

on shell side or excessive

pressure loss

Oil sludging, tube scaling or build

up of both resulting in an

insulating film covering the tubes

The complete heat exchanger

should be thoroughly cleaned

Pressure loss is as

expected, but the

temperature of the oil

rises

Film, scale or restrictions on the

inside of the tubes

The complete heat exchanger

should be thoroughly cleaned

Oil leaking into the

cooling water circuit or

vice versa

Split or perforated tubes

Tubes should be blocked with

hard wooden plugs as a

temporary measure & the

tubestack replaced asap

Inadequate performance Flow rates too low

Unit connected in parallel flow

Check flow rates & increase if

necessary

Reconnect in counterflow as

per section 2.2