Rev D

5

1.3 Potential hazards

Ensure the maximum permissible operating pressure on the primary or secondary side of the heat

exchanger is not exceeded. The heat exchanger or surrounding equipment may be damaged.

NB:

before the oil cooler is disconnected it must be allowed to cool sufficiently and be depressurized to

prevent injury. The supply and returns to the heat exchanger should be isolated to minimise fluid loss.

2 Installation

2.1 Transport / storage

The heat exchanger must be fully drained down prior to transportation. Once drained and fully dry, the

heat exchanger must only be stored indoors within a non aggressive atmosphere. The connections

should be capped to avoid ingress of dirt and contaminants.

2.2 Fitting

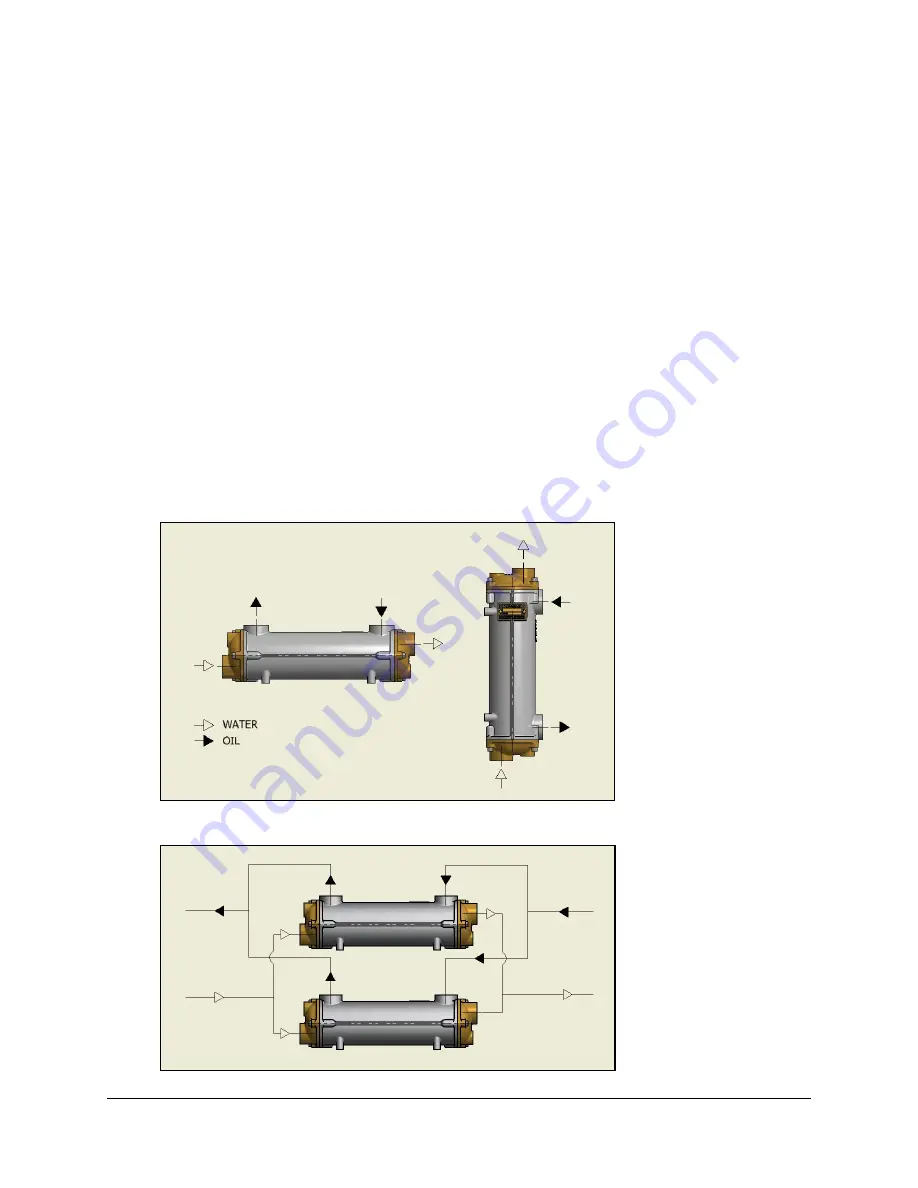

Before fitting, the heat exchanger should be checked for visible signs of damage. The oil cooler can be

positioned horizontally or vertically and should be connected in counterflow so that the fluids flow in

opposite directions, as shown below:

Multiple units can be connected in parallel: