Rev D

7

No oil cooler manufacturer can guarantee that his products will have an indefinite life and for this

reason, we suggest that the cooling system is designed to minimise any damage caused by a leaking

oil cooler. This can be achieved as follows:

1.

The oil pressure should be higher than the sea water pressure, so that in the event of a leak

occurring, the oil will not be contaminated.

2.

When the hydraulic system is not being used, the coolers should be isolated from sea water

pressure.

3.

The sea water outlet pipe from the cooler should have a free run to waste.

4.

Stainless steel sea water pipes and fittings should not be used adjacent to the oil cooler.

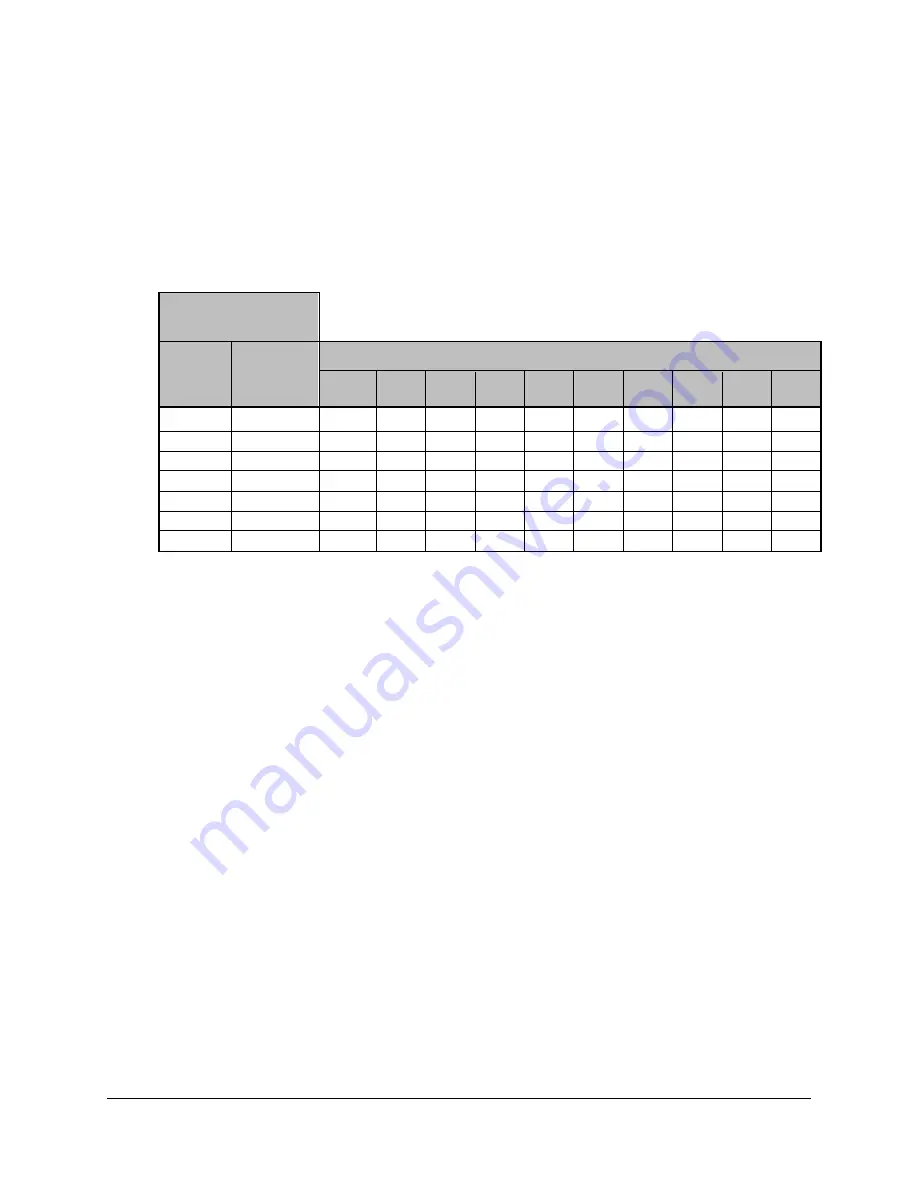

Three Pass Bowman

Heat Exchangers

Oil cooler Max. sea

water flow

l/min

Orifice diameter in mm for max. sea water flow

series

1 bar

2 bar 3 bar

4 bar

5 bar 6 bar

7 bar 8 bar 9 bar

10

bar

EC

50

11

9.5

8.5

8

7.5

7.2

6.8

6.7

6.5

6.3

FC

80

14

12

11

10.0

9.5

9

8.7

8.4

8.2

8

FG

110

17

14

13

12

11

10

10

9.8

9.6

9.3

GL

200

23

19

17

16

15

14

14

13

13

13

GK

300

28

23

21

19

18

17

17

6

16

15

JK

400

32

27

24

22

21

20

20

19

18

18

PK

650

41

34

31

28

27

26

25

24

23

23

2.4 Notes on zinc anodes

The use of zinc anodes in heat exchangers has been employed for some years, generally by

manufacturers using admiralty brass tube or its variants. The purpose of the zinc anode, or zinc pencil

as it is sometimes called, is to prevent dezincification of the brass alloy tubes. As such zinc anode acts

sacrificially in favour of the tube.

There are a number of American and European manufacturers that use these anodes in their products.

Bowman, do not fit zinc anodes as the tubes used in the construction of our coolers are of copper nickel

alloy and as such do not require a zinc anode. It is possible that if this anode is fitted it can actually

destroy the copper oxide film built up by the tube as a natural defence which can allow the tube material

to be attacked.

It is usual with the copper nickel alloys to use an iron anode which allows an iron oxide film to build up

inside the tube which breaks down as a sacrificial element reducing the possibility of corrosion to the

heat exchanger. In Bowman designs it is not practical to fit iron anodes as their size has to be very

generous. Therefore as an alternative a piece of black iron pipework can be placed before the heat

exchanger which in itself acts as sacrificial element protecting the cooler. The Royal Navy has often

used this technique and when the black iron pipework corrodes, it is simply replace with a fresh piece.

We do know that some manufacturers of heat exchangers, mostly those providing copies of the better

known products, often fit zinc anodes incorrectly with copper nickel alloys in error.