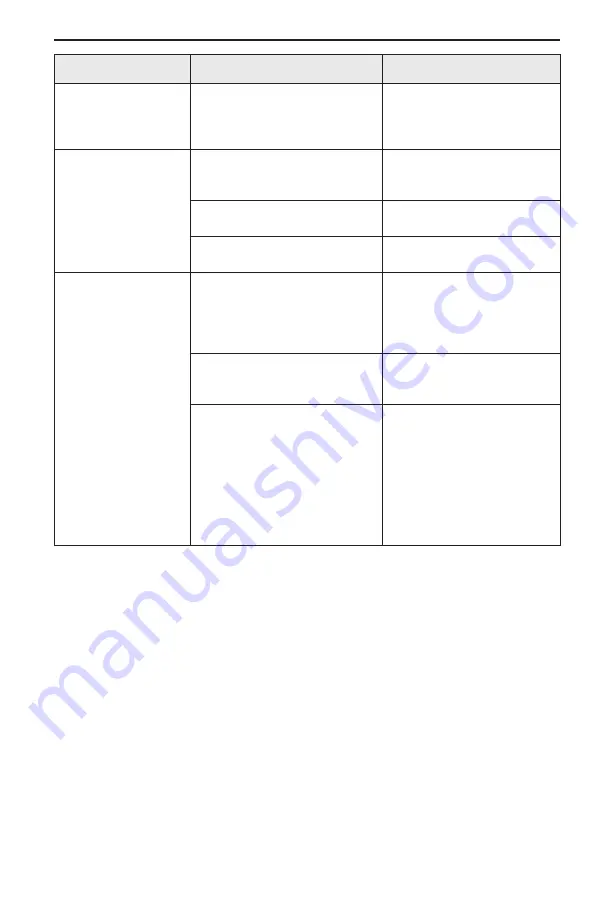

Troubleshooting

4

Problem

Possible Causes

Corrective Action

Engine does not start with

hydraulically powered at-

tachment installed.

• Auxiliary control lever in

activation position.

• Move control lever to Neutral

position.

Rubber track slips on drive

sprocket or comes off

machine

• Track drive tension is not

correct.

• Adjust Track Tension. See

Section 4 – Track Drive

Tension Adjustment.

• Track drive sprocket holes worn

or damaged.

• Replace rubber track.

•

Track guide fingers worn,

damaged or missing.

• Replace rubber track.

Starter does not turn the

engine over.

• Auxiliary hydraulics/ Operator

presence lever is either in

Forward or Reverse position

with no hydraulically powered

attachment installed.

• Move lever to neutral

position.

• Battery is dead.

• Charge the battery.

• If battery does not hold a

charge, replace the battery.

• Electrical connections are

corroded or loose.

• Check electrical connections

for good contact.

• Remove cables from battery

terminals and fully clean

battery terminals and cable

clamps.

• If the cable clamps cannot

be properly cleaned, replace

connectors.