12

Putting into operation

Sprühboy 04s - Airless Edition 10.12

4.1

General requirements on the

compressed-air source

For filling with compressed air that is safe for all

foods, the implement may be connected to an

existing compressed air source or to the compressor

Airboy 04. The implement requires a material

pressure of at least 5 bar and a maximum of 6 bar.

The implement may only be operated with food safe

compressed air.

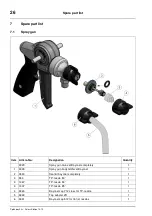

You may only fill the implement with a

maximum agent pressure of 6 bar. If

your compressed-air source has no

means of limiting the maximum agent

pressure to 6 bar, we recommend the

use of our compressed-air control unit

(1).

It is imperative that you use only clean,

dry and food safe compressed air to

operate the implement. Oil lubricated

compressors, possibly with pressure

vessel

with

uncoated

inside,

contaminate the compressed air and

consequently the agent to be sprayed.

If no filter unit (maintenance unit) to

clean the compressed air and also no air

dryer

is

available

behind

the

compressor, oil and rust particles get

into the stainless steel pressure vessels

enter and contaminate the agent.

If your present compressed-air source

does not meet the above requirements,

we recommend you use our three-stage

special filter unit.

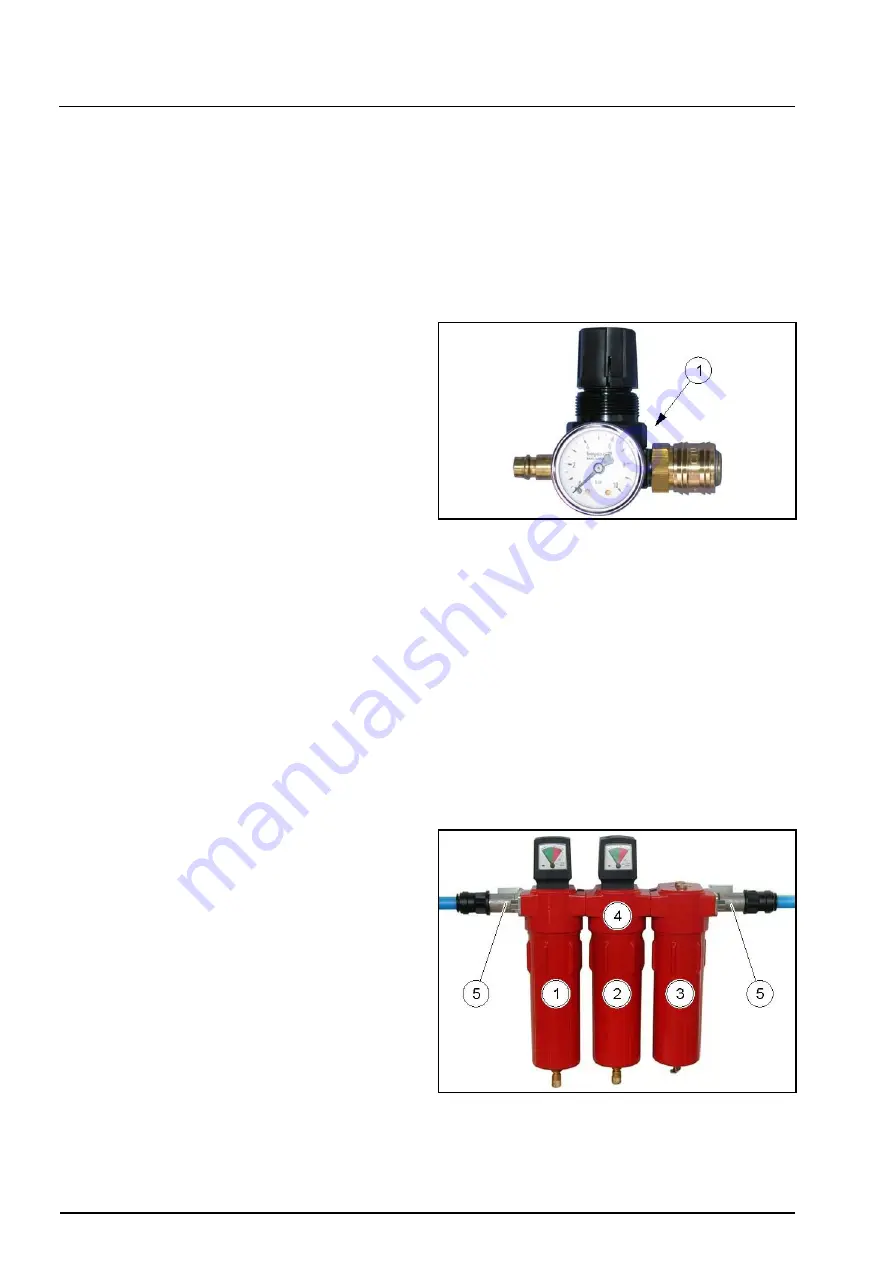

The three-stage special filter unit consists of:

1.

1 x DV 1000. Prefilter with filter element and

automatic condensate discharge with float valve

and differential pressure manometer.

2.

1 x DF 1000. Superfine filter with filter element

and automatic condensate discharge with float

valve and differential pressure manometer. For

higher quality compressed air for pneumatic

control systems.

3.

1 x DA 1000. Activated-carbon filter with filter

element, stopper and closing plate. For highest

quality compressed air as inhaled air, e.g. in

luxury food processing.

4.

2 x Filter housing threaded joint. For

connection of filter units.

5.

1 x Assembly kit. For wall fastening of filter

units.