Cleaning, maintenance and repair

17

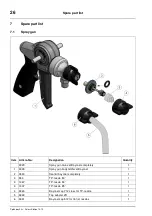

Sprühboy 04s - Airless Edition 10.12

5

Cleaning, maintenance and

repair

Carry out prescribed cleaning and

maintenance work in due time. Prior to

all cleaning, maintenance and repair

work

•

separate the implement from the

compressed air source.

•

discharge the excess pressure from

the stainless steel pressure vessel.

Refer to chapter "Filling the stainless

steel pressure vessel", page 13 in this

regard.

Most malfunctions are caused by

contamination of the compressed air and

the agent to be processed.

Agent nozzle, mesch filter and seal kit

are wearing parts. We recommend you

always keep one spare set of these

components in stock.

To clean the implement, only use

•

hot rinsing water.

•

grease solvent.

•

disinfecting cleaning agents.

•

compressed air.

•

a moist sponge or a moist cloth.

•

never a high pressure cleaning

device.

•

never any alkaline solutions, in

particular no salt brines.

Dispose of all cleaning residues incurred

in

an

environmentally

compatible

manner.

Clean

the

agent-hose

at

regular

intervals.

In case of leaks in the compressed air

system,

slightly

tighten

screw

connections on the spray gun and other

compressed air system components.

These bolted connections may work

loose:

•

because the system is constantly

moving due to the compressed air

and the agent to be sprayed.

•

because of improper handling, e.g. if

the spray gun is dropped.

Every operator may check compressed

air

supplies

and

repair

leaky

compressed air supplies.