13

4 . F a u l t s , e r r o r s a n d t r o u b l e s h o o t i n g

4.1.

Description of fault messages and their causes

Fault

Description

Possible cause

Troubleshooting

The equipment

cannot be started

The equipment

remains idle even

after the required

performance level

was selected

Power supply is not connected

Connect the equipment to power

supply (switch on upstream

safety circuit breakers)

Not found

Disconnect from power

supply

and contact a service

technician

The equipment is

not supplying

enough air

The equipment is

providing a

significantly lower

volume of air

Blocked filter

Disconnect the equipment

from power supply

Replace the filter cloth or

cassette

If the equipment has been in

operation for more than approx.

4 years, clean the heat recovery

exchanger/s

A mechanical obstacle at fresh

air suction or supply air outlets

Check whether the suction

openings of fresh air or supply

air outlets are not mechanically

covered

Remove any obstacles

Visually and by listening check

whether the dampers open

properly

Not found

Disconnect from power

supply

and contact a service

technician

The equipment is

not heating or is

heating

insufficiently

When the heater

has been started,

supply air

continues to be

cold

The electric heater is not

connected to power supply

Connect the equipment to power

supply (switch on upstream

safety circuit breakers) – can

only be done by an authorized

person

Response of the electric

heater’s heat protection

Wait to see if the fault does not

sort itself out after approx. 1

hour

Low maximum capacity of the

heater

Does not constitute a fault

(insufficient capacity designed)

Not found

Disconnect from power

supply

and contact a service

technician

Water is dripping

from the

equipment

Water droplets

form between the

door and body of

the equipment

during operation

The condensate drain siphon is

insufficiently flooded

Disconnect the equipment

from power supply

and flood

the condensate drain siphon

The condensate drain is blocked

with dirt

Disconnect the equipment

from power supply

and clean

the condensate drain including

the siphon

The seal groove is damaged

(the fault can be accompanied

by a whistling sound caused by

air flowing through the gap)

Disconnect the equipment

from power supply

and replace

the seal

Water droplets

form at the

condensate drain

connection point

The condensate drain seal or

line is damaged

Disconnect the equipment

from power supply and

re-seal

the condensate drain

Not found

Disconnect from power

supply

and contact a service

technician

Summary of Contents for DUPLEX 250 Easy

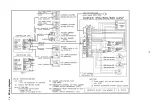

Page 23: ...23 7 4 Wiring diagram ...