© Magna Electronics Pte Ltd.

Page 10

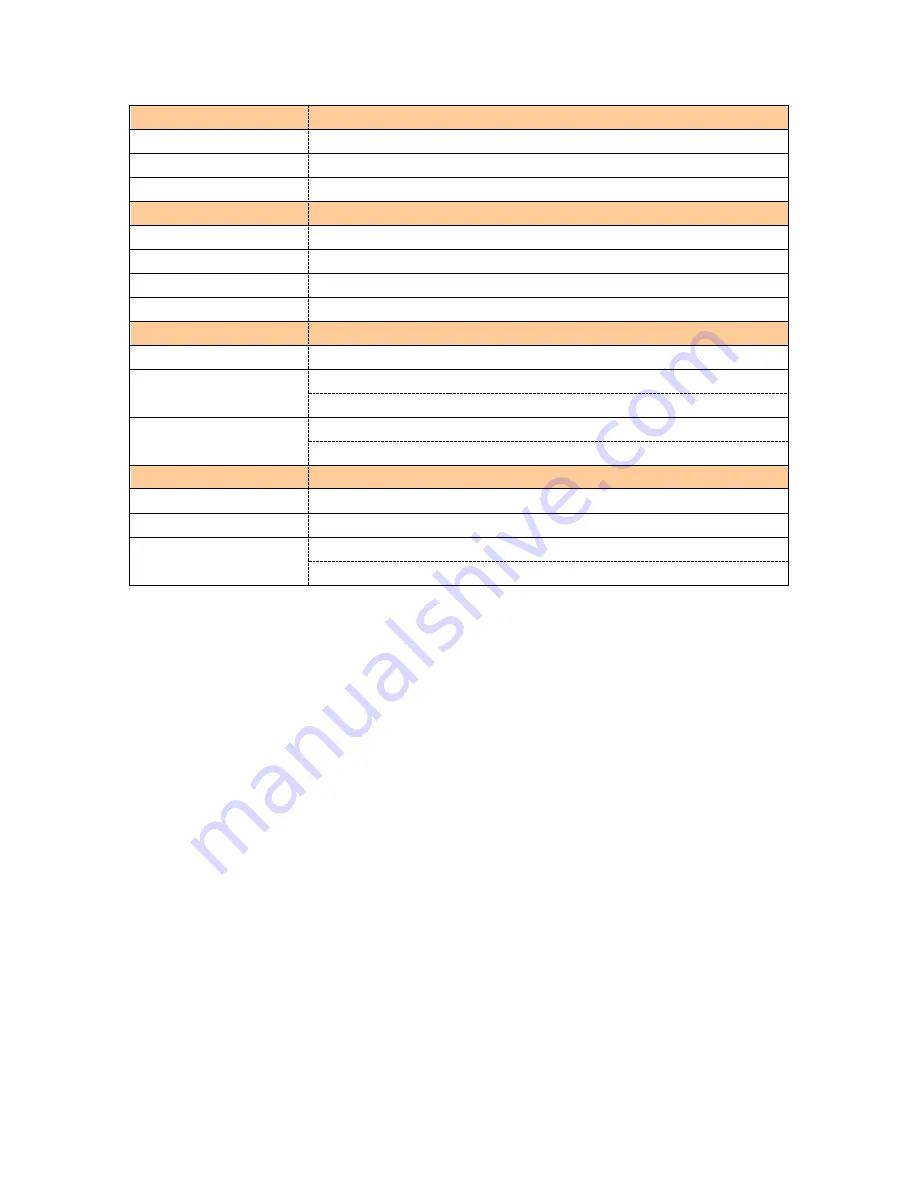

8. SPECIFICATIONS

MATERIALS

Bolt Pins

SS17-4PH, 10mm Thick, 13mm stroke (2 Pieces)

Strike Plate

SS304, 3mm Thick

Lock Face Plate

SS304, 3mm Thick

MECHANICAL

Cycle life

> 100,000

Strike Gap

< 8mm

Holding Force

> 10,000N (1000kg)

Door Misalignment

±

8mm

ELECTRICAL

Voltage at Lock

12

– 24VDC ±15%

Current Usage

Standby Current

< 50mA@12V

< 30mA@24V

Operating Current

*

< 1800mA@12V < 600mA@24V

Monitor Switches

Bolt position

– 30VDC, 0.1A

Door position

– 100VDC, 0.5A

CERTIFICATIONS

Patent

Pending NZ599955

FCC

Part 15 Subparts A & B

– Unintentional Radiators

CE

EN 61000-6-1: 2007, EMC Directive 2001/108/EC Immunity

EN 61000-6-3: 2007, EMC Directive 2001/108/EC Emissions

*

Initial power up of the lock requires up to 1800mA@12VDC and up to 600mA@24VDC for up to 6 seconds but only occurs

when the power has been completely removed and re-applied.

Normal Operating Current after initial power up is <250mA@12VDC and <200mA@24VDC.

9. MAINTENANCE

The COBALT has been lubricated at assembly and applying any other type of lubricant may void the warranty.

Removing the lock cover may void the warranty. A dry cloth can be used to polish the stainless steel face plate and

strike plate as required.

10. WARRANTY

The COBALT is covered with a manufacturers 12month warranty against faulty or malfunctioning parts,

components or product. At the

manufacturer’s discretion, either a replacement lock or affected part will be supplied

to remedy the fault or the lock can be returned at the custo

mer’s expense to the manufacturer for repair.

Mistreatment or ill-use of the lock may void the warranty. YNOTLOC and COBALT are trademarks of Magna

Electronics Pte Limited. Magna Electronics Pte Limited will not be liable for any direct, indirect, incidental or

consequential loss or damage in any way related to this product.

11. UPGRADE

The COBALT is designed and manufactured by Magna Electronics Pte Limited. Magna Electronics Pte Limited

reserves the right to upgrade or change this product without prior notice.

For more information visit www.ynotloc.com