9

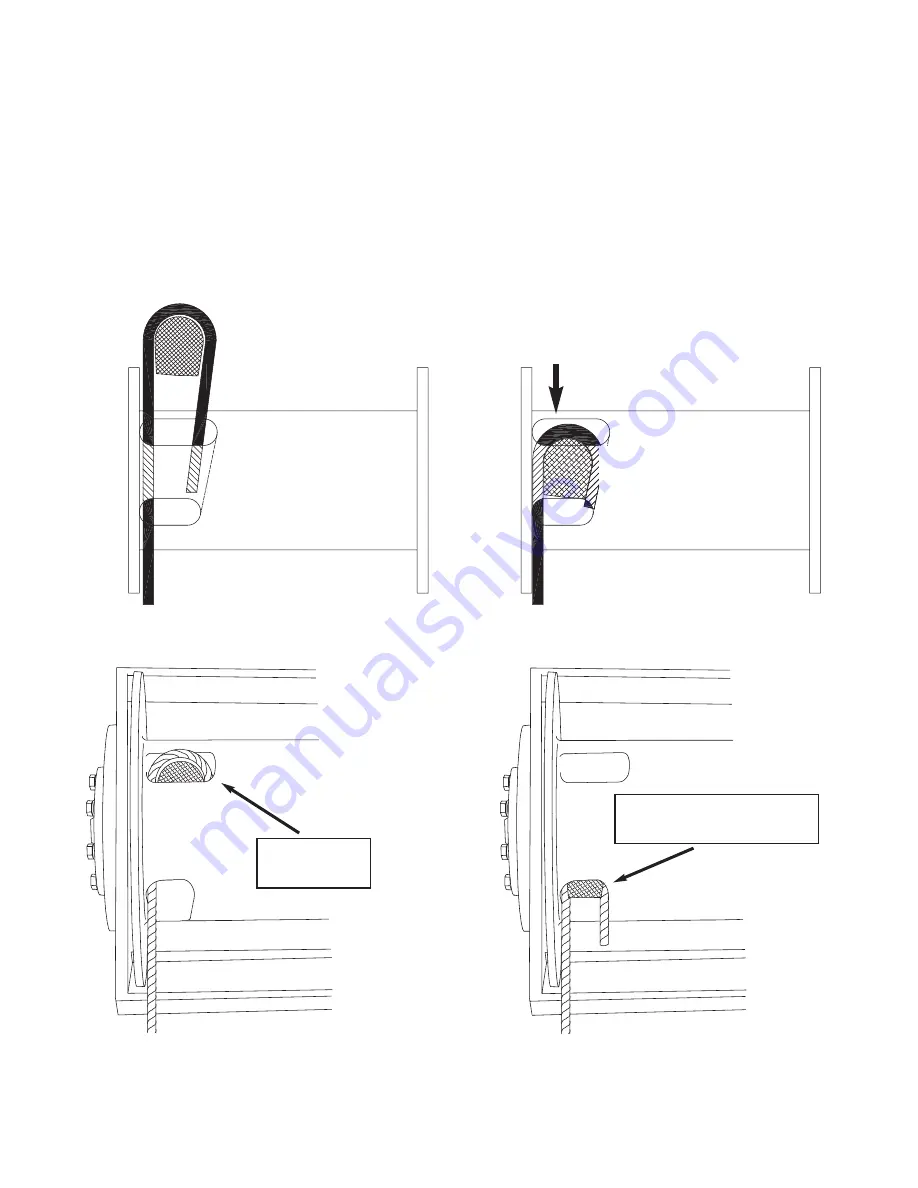

Using a hammer and brass drift, drive the wedge as

deep into the pocket as possible to ensure it is fully

seated and no further movement is detected. Applying

a load on the wire rope will also help seat the wedge in

the pocket.

Check to ensure the wedge does not protrude from

either end of the pocket, causing it to interfere with

proper spooling of wire rope onto the drum (see figures

3 & 4). If there is interference or the wedge does not

seat firmly, contact the Braden Product Support

Department at 918-251-8511 to determine the proper

wedge size.

It is important that the wire rope have the proper ten-

sioning when it is installed on the drum. When the wire

rope is first installed, you should operate the hoist, with

light to moderate loads, with reeving that let’s you place

these loads on the block and the drum with all the rope

off the drum except for the last three wraps.

Drive from

this side

Wedge and wire rope

fully seated in pocket

Figure 1

Figure 2

Correct Installation

Incorrect Installations

Wedge not

fully seated

Wedge pulled too far

through anchor pocket

• Wire rope not tight against wedge

• Wedge may be too large

• “Dead” end of wire rope and/or wedge may

interfere with proper spooling

• Wedge may be too small

Figure 3

Figure 4