9

01 and 02 DRUM – ANCHOR

Remove both sheet metal covers from the end bracket of

the winch. Pull the end of the cable through the opening in

the drum flange and out through the end bracket as shown

in Figure 1. Form the cable around part 1 of the wedge as

shown in Figure 2, and pull the assembly into the anchor

pocket (part 2 and the nut are not attached to part 1 at this

time). Access the threaded rod attached to part 1 through

the other opening in the end bracket and install part 2 and

the nut. On large diameter cable, it may be necessary to

hammer on the cable looped around part 1 to force it far

enough into the anchor pocket to attach part 2.

It is important for the dead end of the cable to extend be-

yond the end of part 2, as shown in Figure 2, but not far

enough to come in contact with the end bracket when winch

is operating. A load should be applied to the live end of the

cable to properly seat the anchor. After initial load is ap-

plied, tighten nut holding part 2 in place to 11 ft-lbs. A mini-

mum of five wraps of wire rope should remain on the cable

drum at all times. Refer to General Safety Recommenda-

tions section of this manual for additional information.

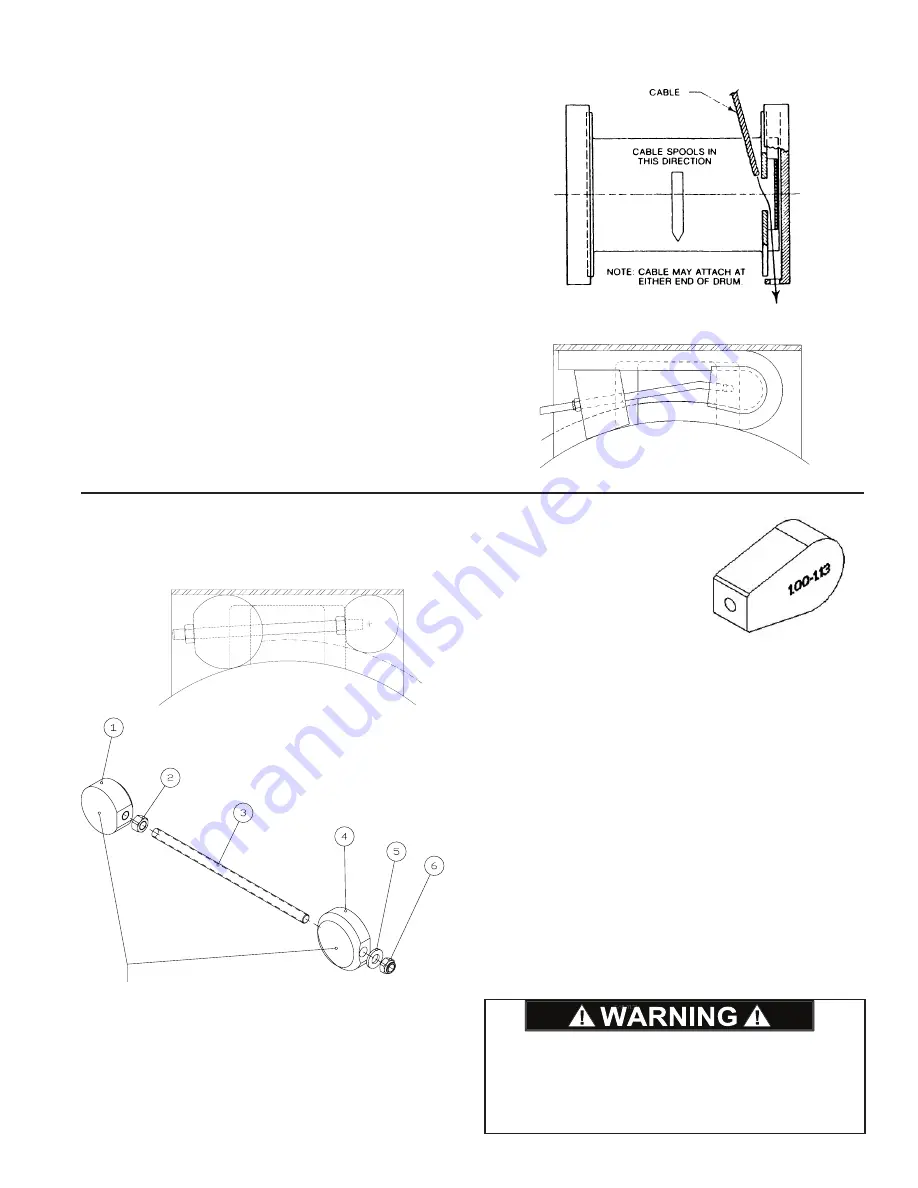

3-piece Cable Anchor Installation

(specific to model CH400)

Install threaded rod (Item 3) into Item 1 until it bottoms,

then tighten jam nut (Item 2) against Item 1.

Feed cable through opening in drum flange until it extends

outside cable pocket 2 to 4 inches.

Insert partially assembled anchor (Items 1, 2, 3) into the

cable pocket with flat side of Item 1 against the drum

flange. The anchor will wedge between the cable and the

top of the cable pocket.

Working from the other end of the cable pocket, install

Item 4 onto the threaded rod. Be sure to place the flat side

of Item 4 against the drum flange, then install the rounded

end onto the threaded rod first so the washer (Item 5) and

locknut (Item 6) will seat against the flat end.

Install the washer and locknut onto the threaded rod and

tighten securely to 45 ft-lbs. (This is the torque value of the

1/2-13 stainless-steel rod).

Apply a light load of 1,000 to 2,000 pounds on the cable

and carefully spool it onto the drum. Retighten the nut

again to 45 ft-lbs.

These surfaces face toward

drum flange when installed.

Figure 3

The cable anchor is not designed to hold the rated load

of the hoist. DO NOT apply full rated load until five or

more wraps of cable are on the drum. A sudden loss

of load control could cause property damage, personal

injury, or death.

SPECIAL OFFSHORE BREAKAWAY ANCHOR

NOTE:

Confirm that the cable

clamp assembly is suitable

for your rope size by read-

ing the size range (in inches)

stamped on part itself.

Example

01 AND 02 DRUM – ANCHOR

Remove both sheet metal covers from the end bracket

of the winch. Pull the end of the cable through the

opening in the drum flange and out through the end

bracket as shown in figure 1. Form the cable around

part 1 of the wedge as shown in figure 2, and pull the

assembly into the anchor pocket (part 2 and the nut are

not attached to part 1 at this time). Access the threaded

rod attached to part 1 through the other opening in the

end bracket and install part 2 and the nut. On large

diameter cable, it may be necessary to hammer on the

cable looped around part 1 in order to force it far

enough into the anchor pocket to attach part 2. It is

important for the ‘dead’ end of the cable to extend

beyond the end of part 2, as shown in figure 2, but not

far enough to come in contact with the end bracket

when the winch is operating. A load should be applied

to the ‘live’ end of the cable to properly seat the anchor.

After the initial load is applied, check the tightness of

the nut holding part 2 in place and tighten it if required.

A minimum of five (5) wraps of wire rope should remain

on the cable drum at all times. Refer to “General Safety

Recommendations” for additional information.

–– 7 ––

Figure 1

Figure 2

HYDRAULIC CIRCUITS

SINGLE SPEED CIRCUIT

2 SPEED CIRCUIT

Part

2

Part

1

Summary of Contents for CH330

Page 2: ...2...