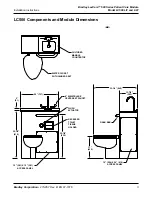

Bradley LavCare 500 Series Patient Care Module

Model LC500 L/F and L/W

Installation Instructions

4

Bradley Corporation

215-857 Rev. B; EN 97-1016

Installation Instructions

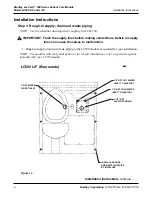

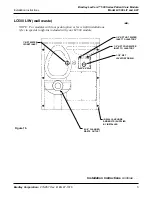

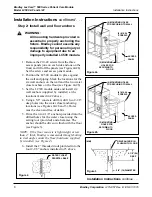

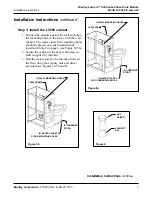

Step 1: Rough-in supply, drain and waste piping

NOTE: Use the submittal drawing when roughing in the LC500.

IMPORTANT: Flush the supply lines before making connections. Debris in supply

lines can cause the valves to malfunction.

1. Rough in supply, drain and waste piping to the LC500 module as required for your installation.

NOTE: For modules with foot pedal option or for retrofit installations, refer to special rough-ins

included with your LC500 module.

Figure 1a

LC500 L/F (floor waste)

Installation Instructions

continue . . .

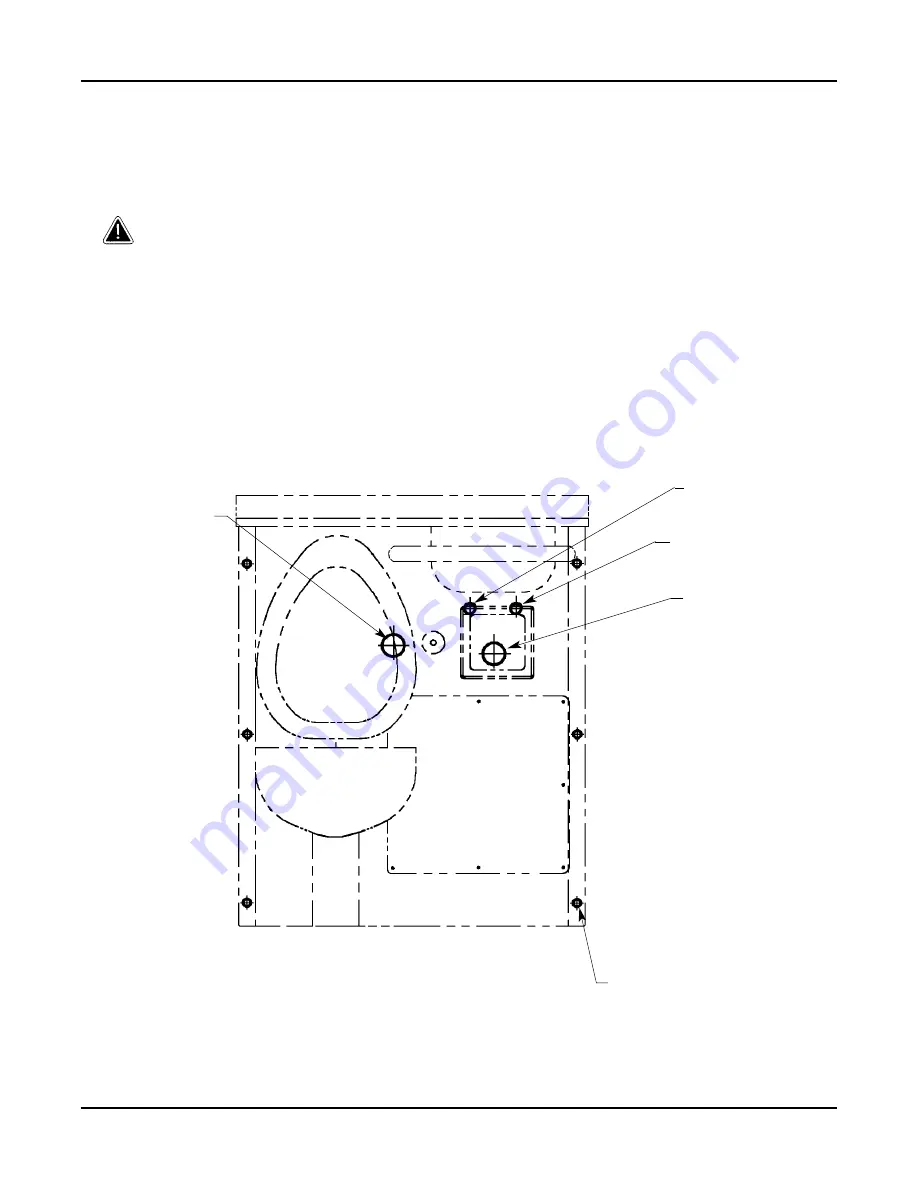

1/2 NPT HOT WATER

INLET TO LAVATORY

1/2 NPT COLD WATER

INLET TO LAVATORY

1-1/2 NPT

LAVATORY DRAIN

1 NPT WATER

CLOSET INLET

(6) WALL ANCHORS

AND BOLTS (SUPPLIED

BY INSTALLER

(MM)